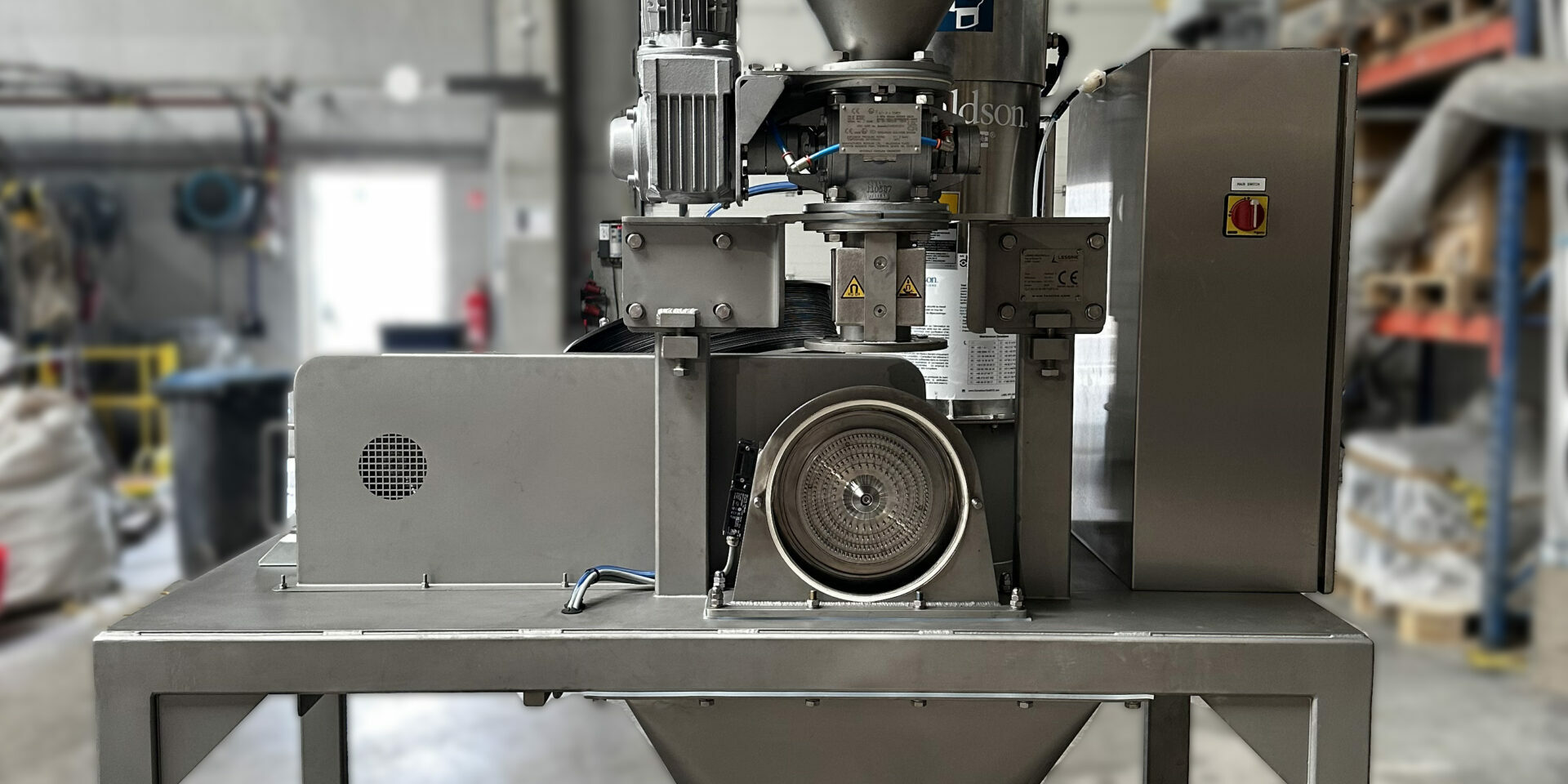

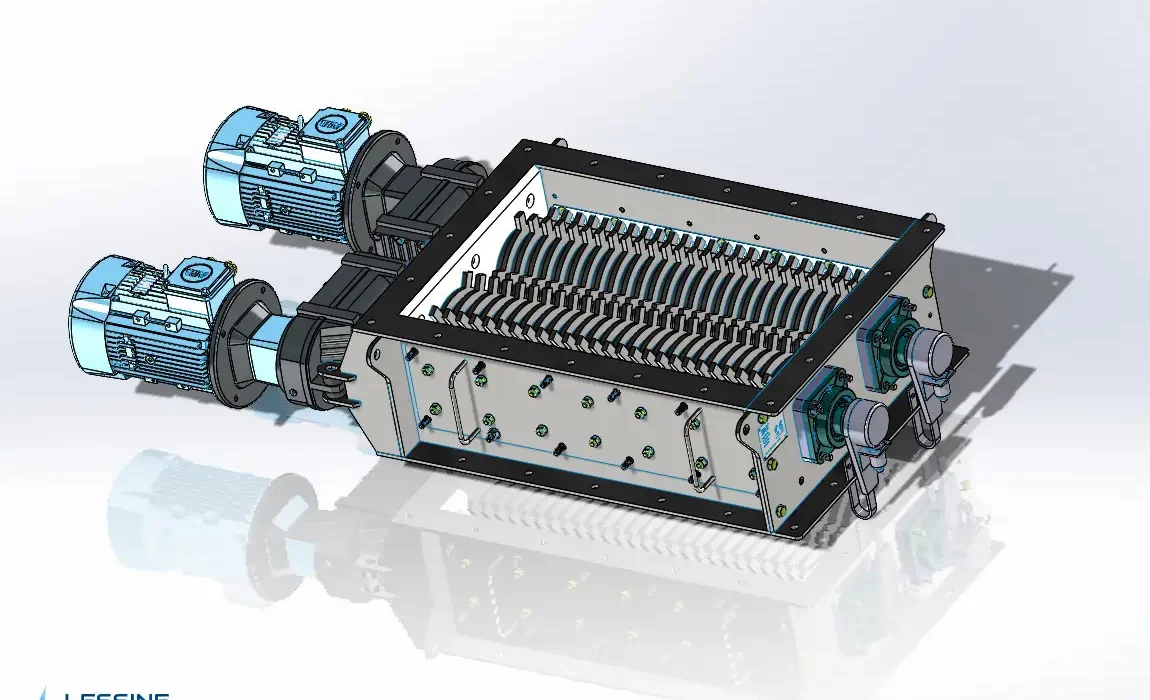

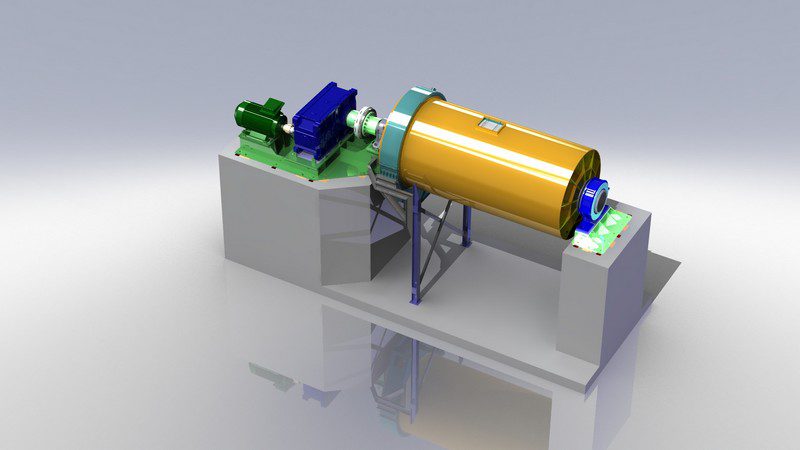

Universal solution for very fine milling

Lessine’s pin mills are designed to reduce products with a hardness of less than 3 Mohs, achieving a very fine output particle size, down to 10µ. This type of mill is ideal for a wide range of industrial applications.

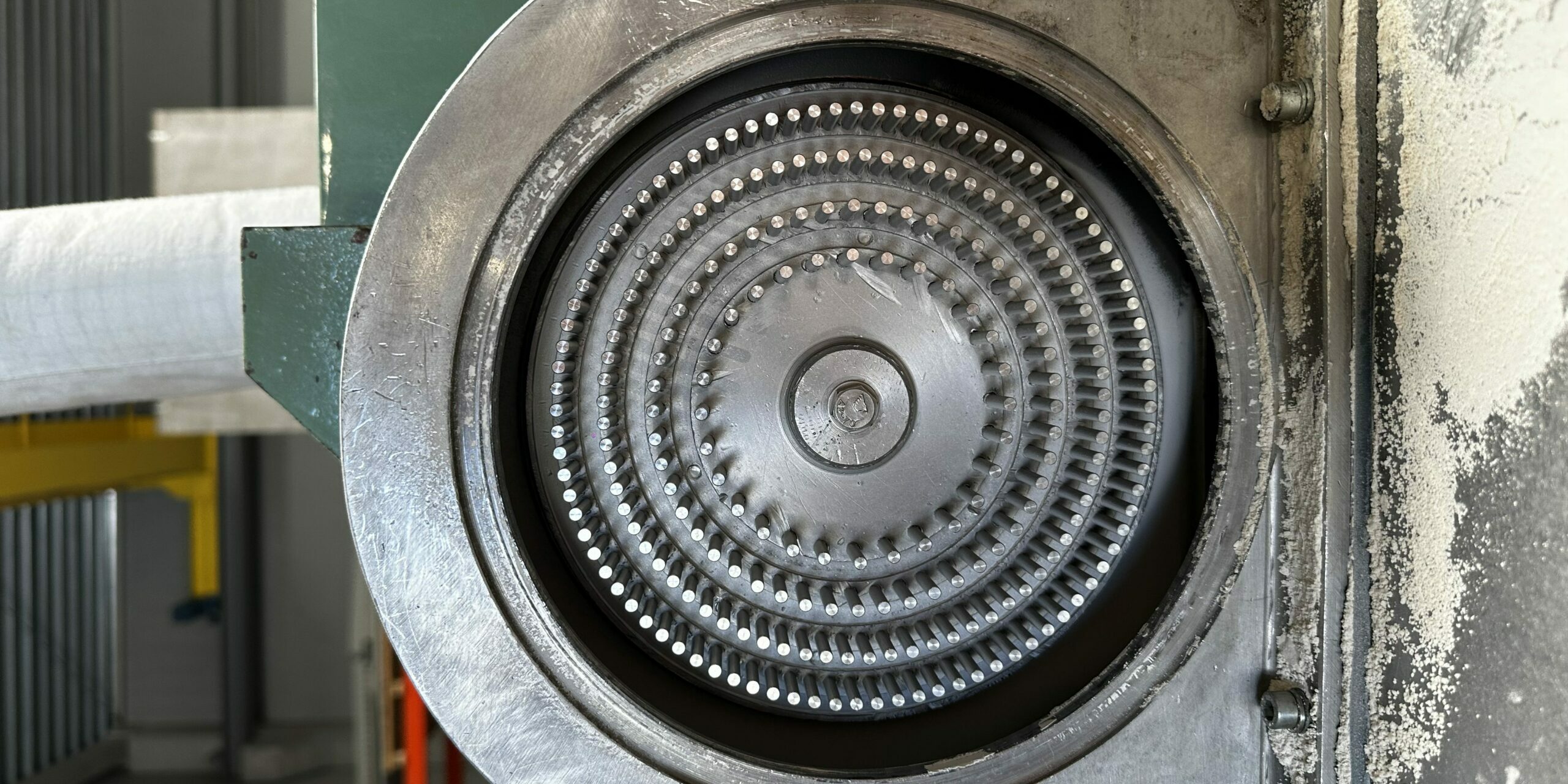

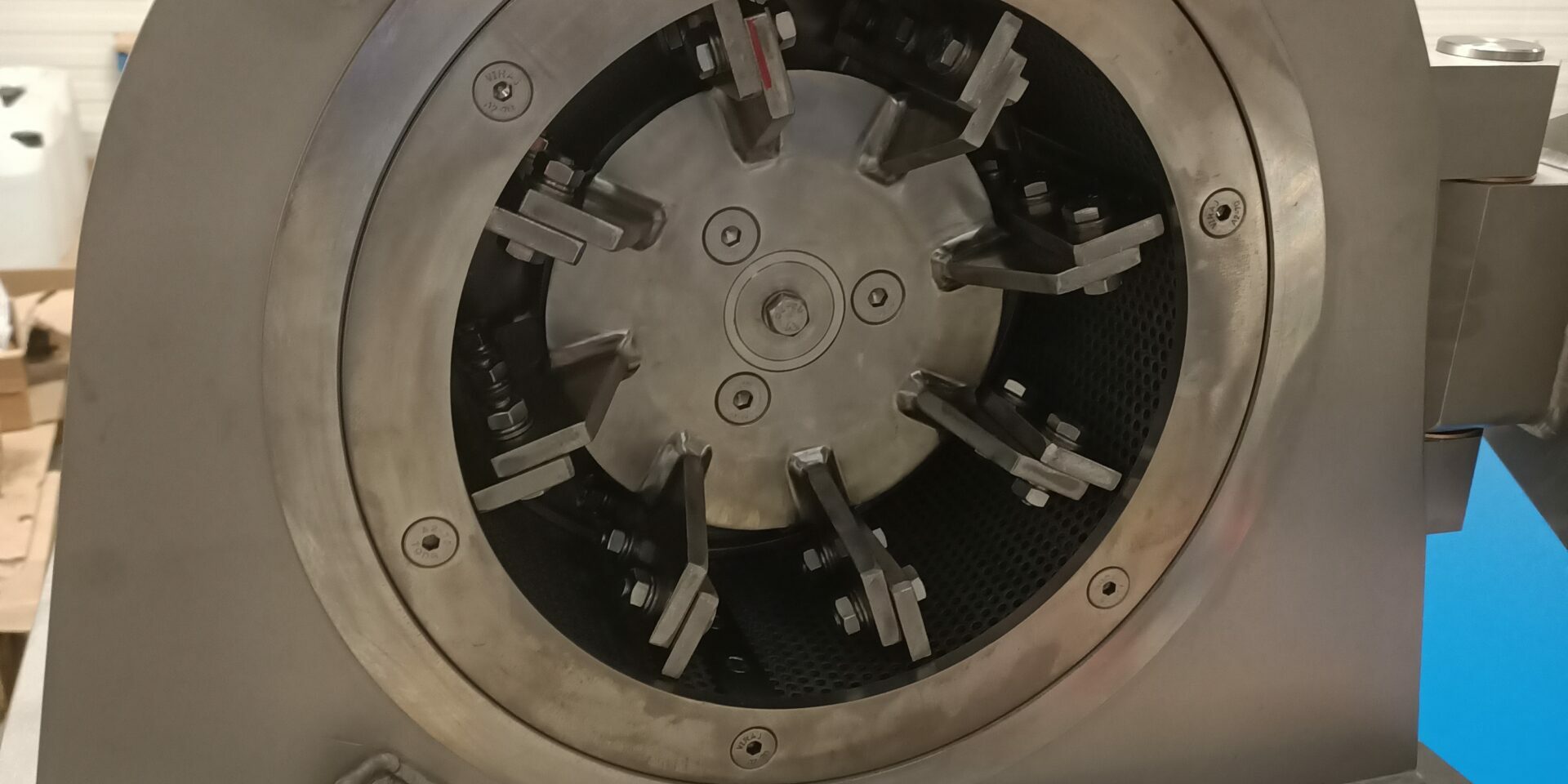

Operating principle

Pin mills are als known as universal mill, centrifugal mill, or fin impact mill.

The product to be milled is injected into the center of a vertical circular stator-rotor assembly. The rotor, rotating at high speed, draws in the product and propels it towards the outlet. Milling occurs both through particle collision and their passage through the rotating milling elements. A large airflow during milling limits product heating, ensuring efficient disintegration without altering the product.

Pin mill applications (universal mill, centrifugal mill, fin impact mill)

The pin mill is suitable for reducing materials that are:

- Mineral, organic, or vegetable with a hardness less than 3.5 Mohs

- Dry, slightly moist, or low in fat content

- Slightly clogging

It is used in various industrial sectors such as :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages of the pin mill

- Complete adjustability to the treated product

- Effective disintegration of agglomerates

- Minimal product heating during milling

- Low energy consumption

- Easy maintenance via an access door

- Machine stability ensured

- Fine and homogeneous particle size

- Minimal generation of fines