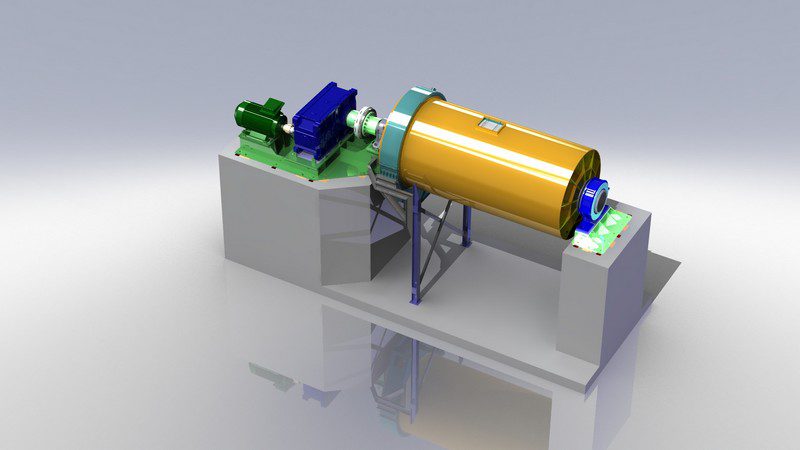

Industrial milling solution for materials of all hardnesses

Lessine’s batch ball mills are grinding devices that reduce numerous materials to powder, regardless of their hardness, ensuring an output fineness of to 5µ. They meet the grinding needs of materials in various industries.

Operating principle

The grinding process in batch ball mills also known as ball mill or ball grinding mill proceeds as follows : balls are placed with the product in a rotating drum. Grinding results from the friction and impact created by the balls falling against the product and the collision of particles with each other over a given time. At the end of the grinding period, the product is discharged from the mill (without the balls, which remain in the drum). If necessary, the product is then sieved to separate any remaining coarse particles. The intensity of grinding depends primarily on the drum speed, the size and material of the balls, and the residence time of the product in the chamber.

The final particle size is defined by the grinding time, with a high level of repeatability cycle after cycle.

Various linings available : Ceramic, rubber, abrasion-resistant steel, etc.

Various options available : Cooling jacket, operation under controlled atmosphere, etc.

Applications of the batch ball mill (ball mill, ball grinding mill)

The batch ball mill is widely used in the following sectors :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages of the batch ball mill

- Control of the final product particle size through grinding time

- Flexibility of use

- Easy transition from one grinding process to another

- Possibility of heating or cooling the drum

- Easy installation and maintenance

- Long service life of grinding balls

- Adaptability of the quality of balls and drum lining

- Grinding in wet or dry conditions