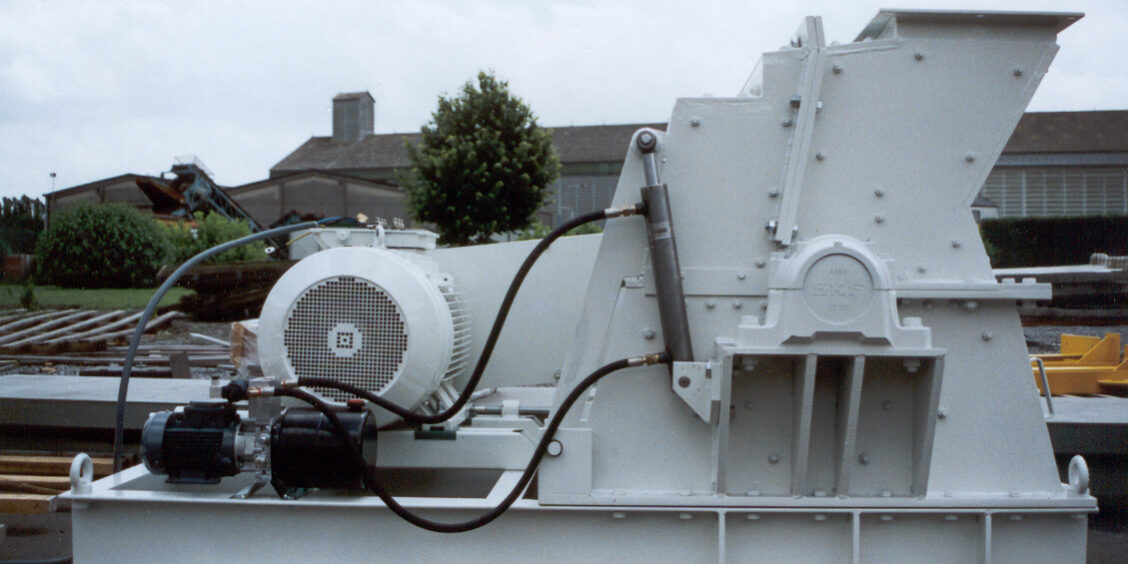

Powerful solution for medium to heavy mass reduction

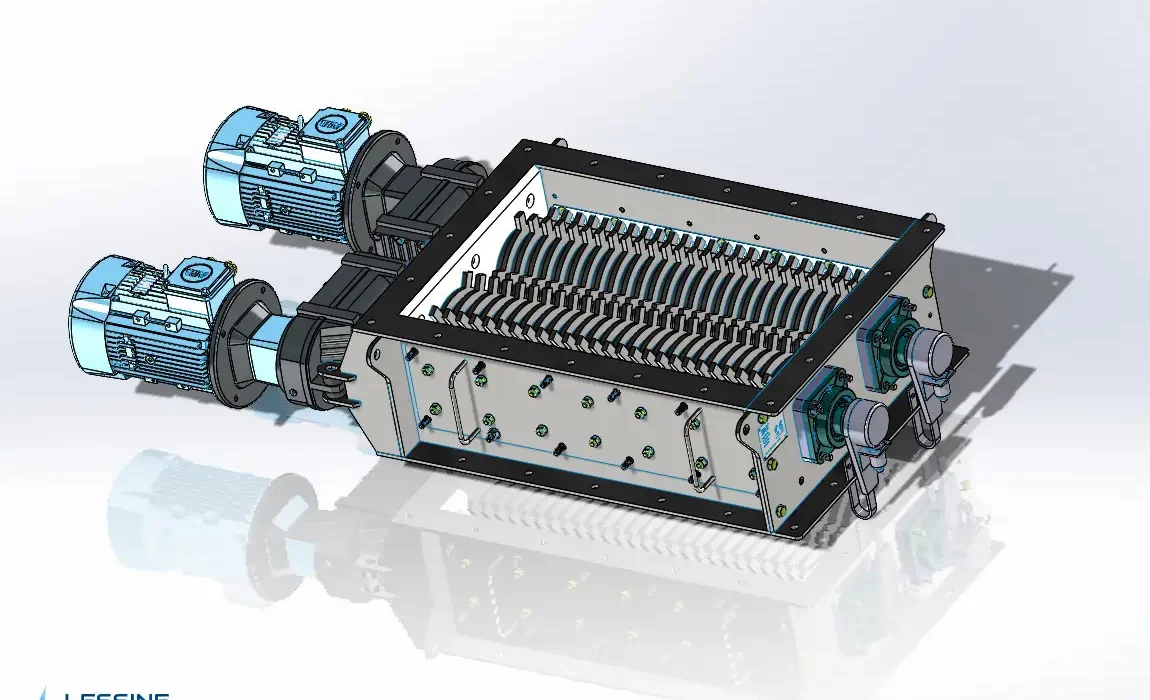

Lessine’s hammer mills, also known as hammer crushers, are designed to efficiently reduce medium to heavy mass products. By striking the material with pendulum hammers, they achieve a final particle size ranging from medium (20 mm) to fine (200 µm), ensuring a uniform particle size distribution.

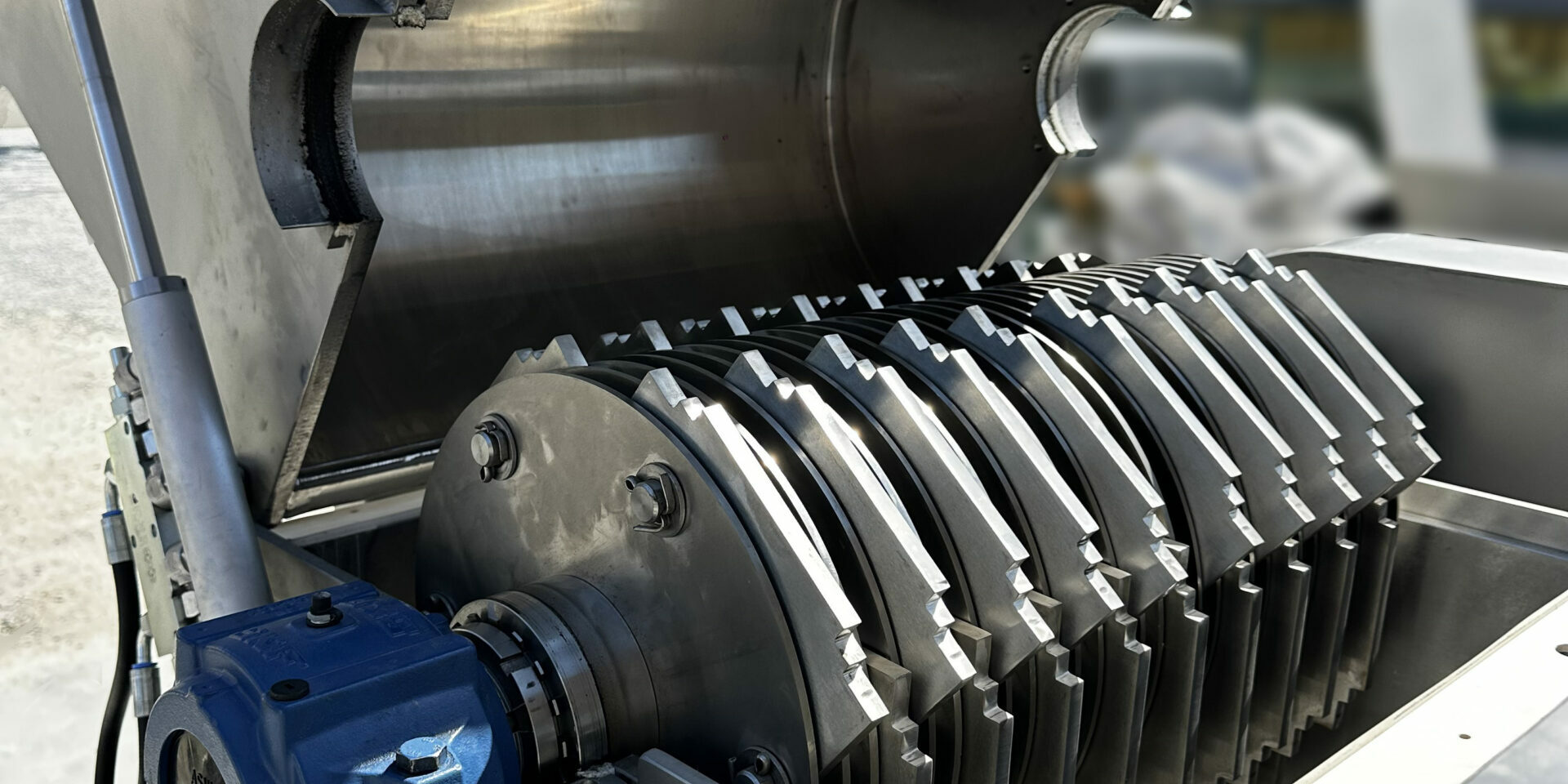

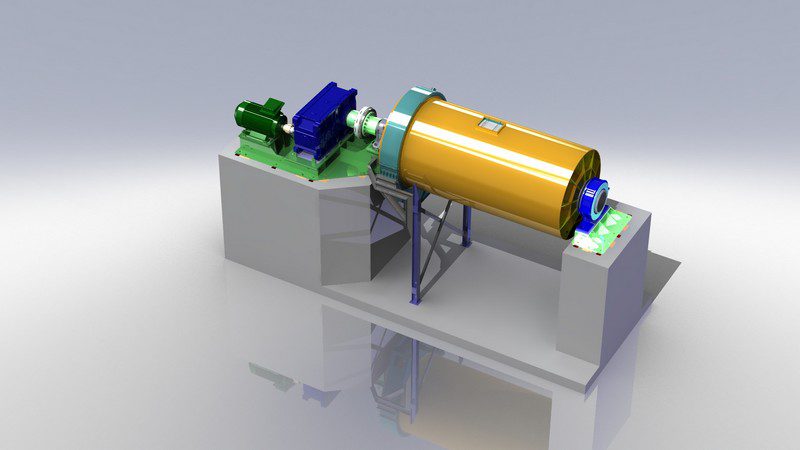

Operating principle

Hammer mills also known as hammer crusher or flail mill, feature pendulum hammers that strike the product against a lining. These hammers are mounted on a rotor rotating at medium or high speed, facilitating the product’s aspiration into the mill. The product is then milled on a screen, with the determining the final particle size.

Hammer mill applications (hammer crusher, flail mill)

Depending on its configuration, the hammer crusher can handle a variety of soft, low, medium, or heavy mass, abrasive products in sectors such as :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Avantages of the hammer mill

- Reduction ratio: up to 20:1

- Complete adaptation to specific needs

- Choice of hammer type and rotation speed according to application

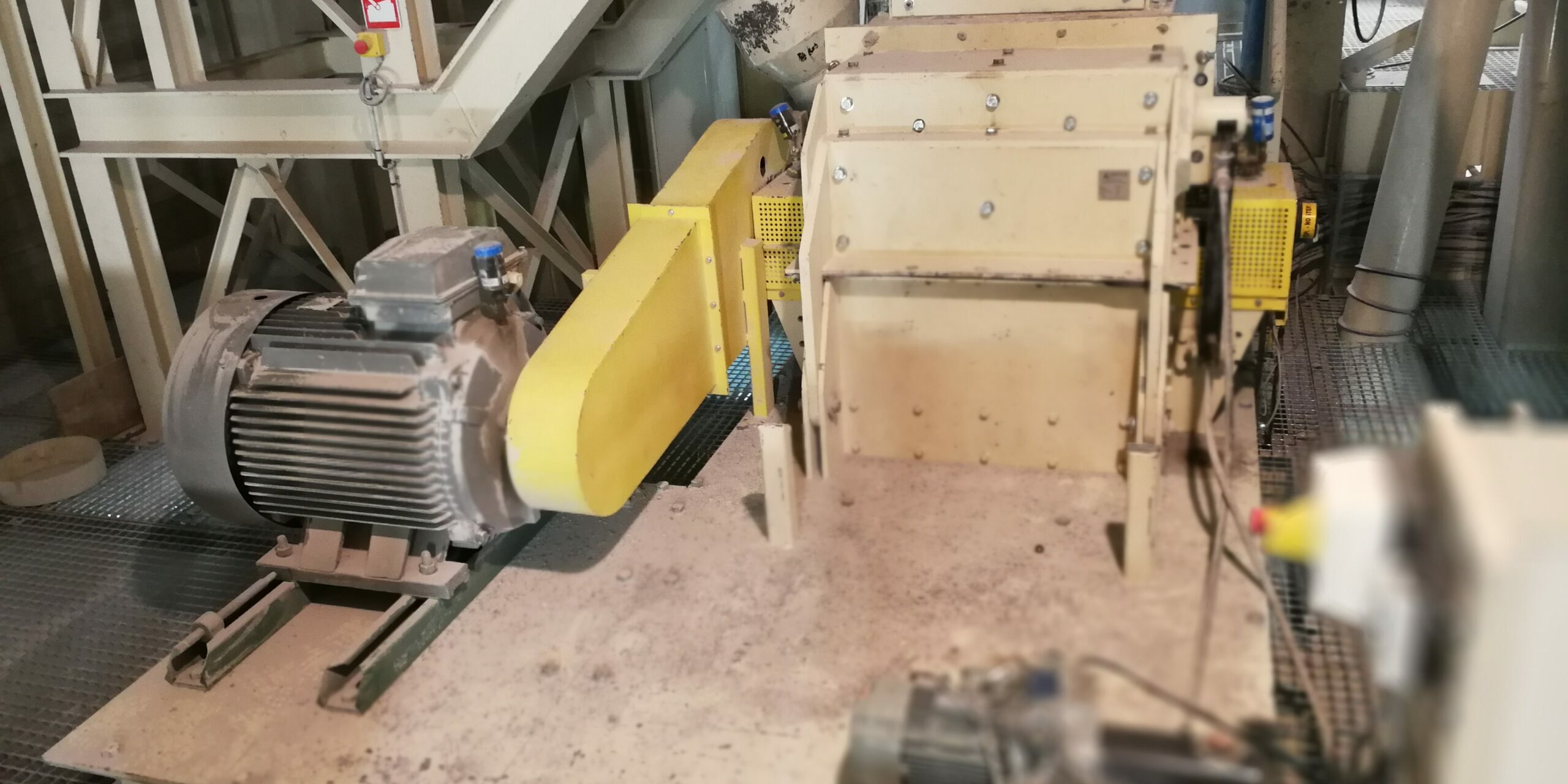

- Intensive industrial use

- Easy access for maintenance and wear control

- Easy screen replacement