Solution for transporting powdery materials

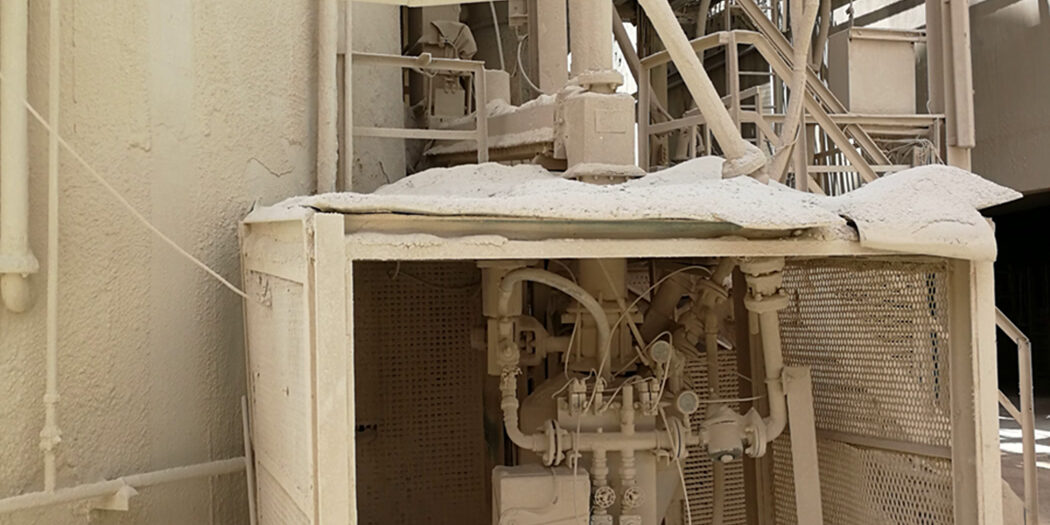

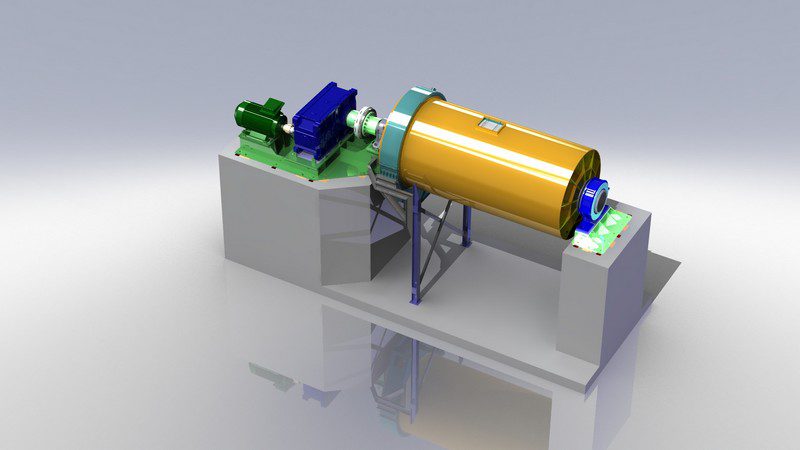

Dense pneumatic conveying is an optimized method for moving powdery materials (such as powders) through a pipeline network using compressed air or another gas. Unlike diluted phase conveying, which operates at high speeds, dense phase conveying stands out with lower speeds and higher pressures, allowing large quantities of materials to be transferred with less air. This system is particularly effective for long distance conveying.

Operating principle

In dense pneumatic conveying also known as dense pneumatic transport, the material is introduced into a pipeline and moved by compressed air at speeds ranging from 15 to 25 m/s, forming “plugs” or segments of dense material. The system design and air pressure control manage the flow speed and density, preventing separation between the material and the air. Product transfer in pulsed plugs, with compressed air speeds ranging from 5 to 12 m/s, is particularly suited for long distances, ensuring enhanced safety. Air activators along the piping are used to regulate compressed air supply, guaranteeing smooth and safe transport.

Applications of dense pneumatic conveying (dense pneumatic transport)

Dense pneumatic conveying is ideal for handling grains, granules, and free-flowing fine powders in the following industries :

- Circular economy and recovery

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages

- Dust and gas sealing

- Reduced abrasion

- Minimal segregation of mixed products

- Gentle handling of sensitive products

- No contamination

- Low maintenance costs