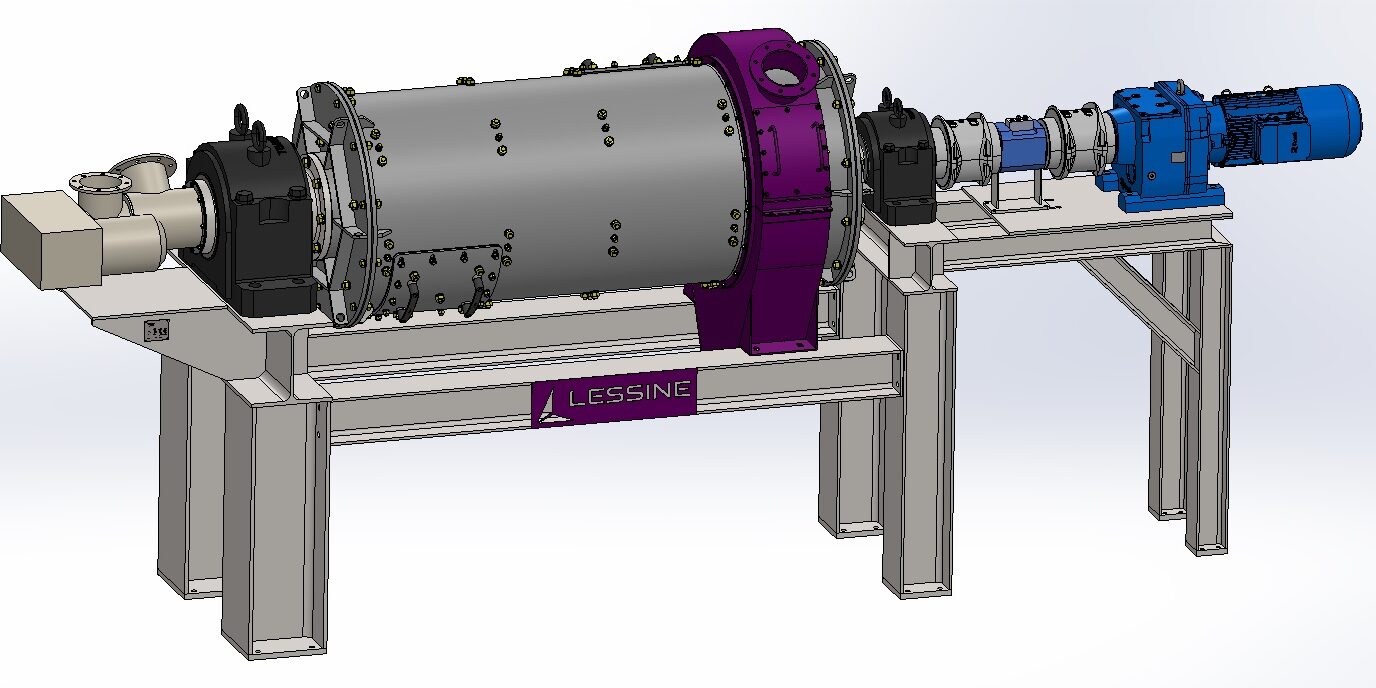

Robust and flexible solution for industrial bulk milling

Lessine’s continuous ball mills are designed for impact, friction, and attrition milling, with a wide range of throughput rates. They allow for the grinding of various materials, ensuring a finished product fineness adaptable to the needs and requirements of various industries.

Operating principle

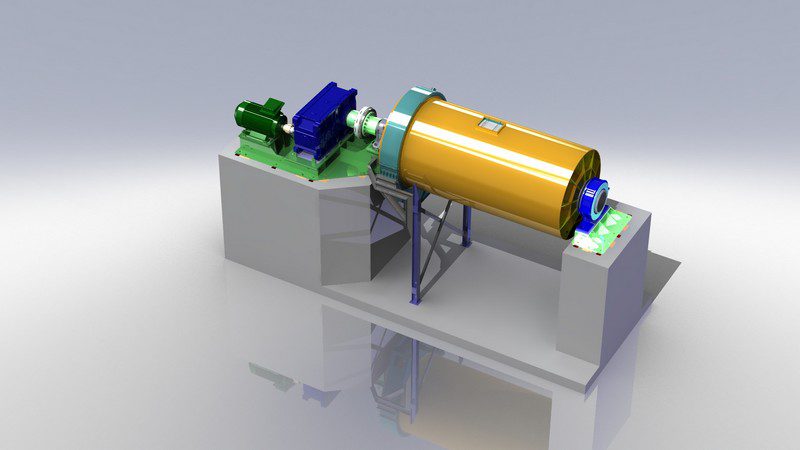

Continuous ball mills also known as ball mill or ball grinding mill consist of a rotating drum containing a grinding media charge, such as balls or rods, into which a material, dry or liquid, is finely ground. The drum is filled to about one-third of its volume with the grinding media. As the drum rotates around its axis at an optimized speed for milling, the material is ground by impact, friction, and attrition. The output product then undergoes particle size separation by screening, air classifier, or hydrocycloning, depending on the desired particle size, with the oversize material recirculating into the mill. The continuous ball mill can also be ventilated for drying or cooling, offering great flexibility in material processing.

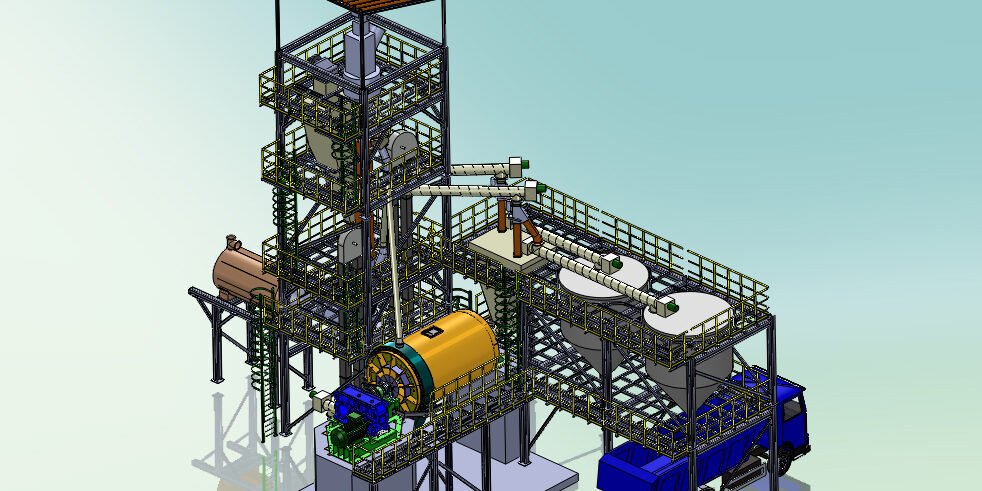

Applications of the continuous ball mill (ball mill, ball grinding mill)

The continuous ball mill is used in the following sectors:

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

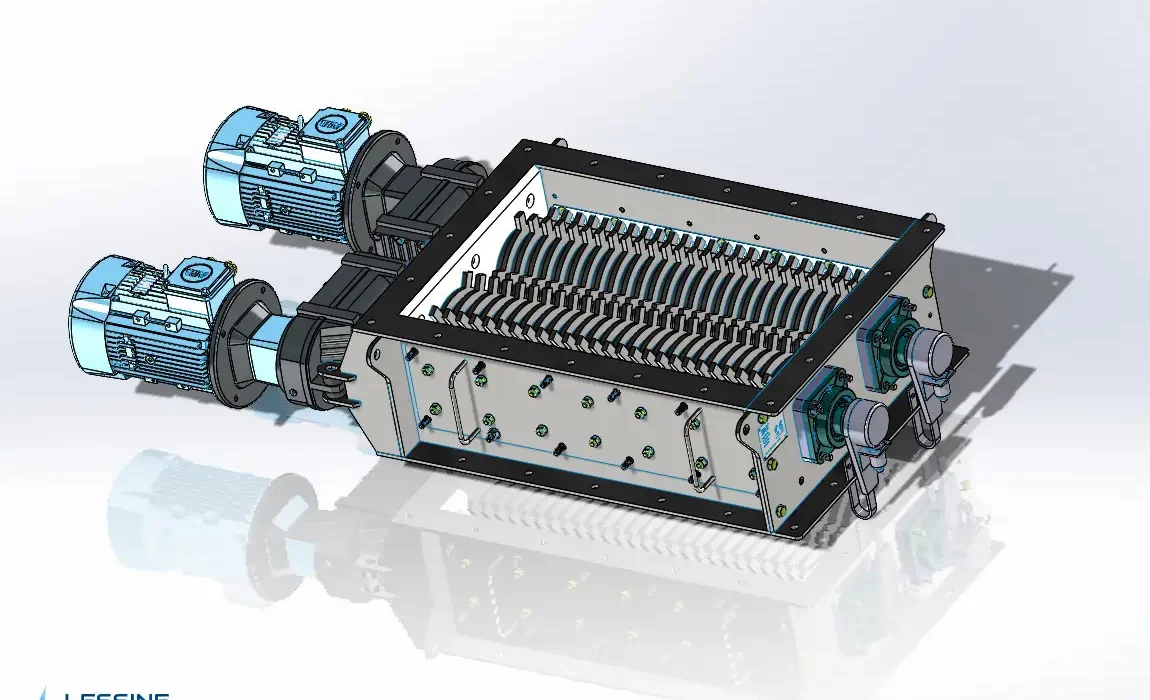

Advantages of the continuous ball mill

- Continuous operation, in dry or wet conditions

- Medium to high throughput rates

- Discharge by overflow or peripheral discharge

- Ventilation for drying or cooling

- Efficient particle size separation with recirculation of oversize material

- Low maintenance costs

- High reliability

- Control of final product particle size

- Flexibility of use

- Easy transition from one milling process to another

- Easy installation and maintenance

- Long service life of grinding media

- Adaptability of grinding media and drum lining quality

- Wet or dry grinding