Fast and homogeneous mixing solution

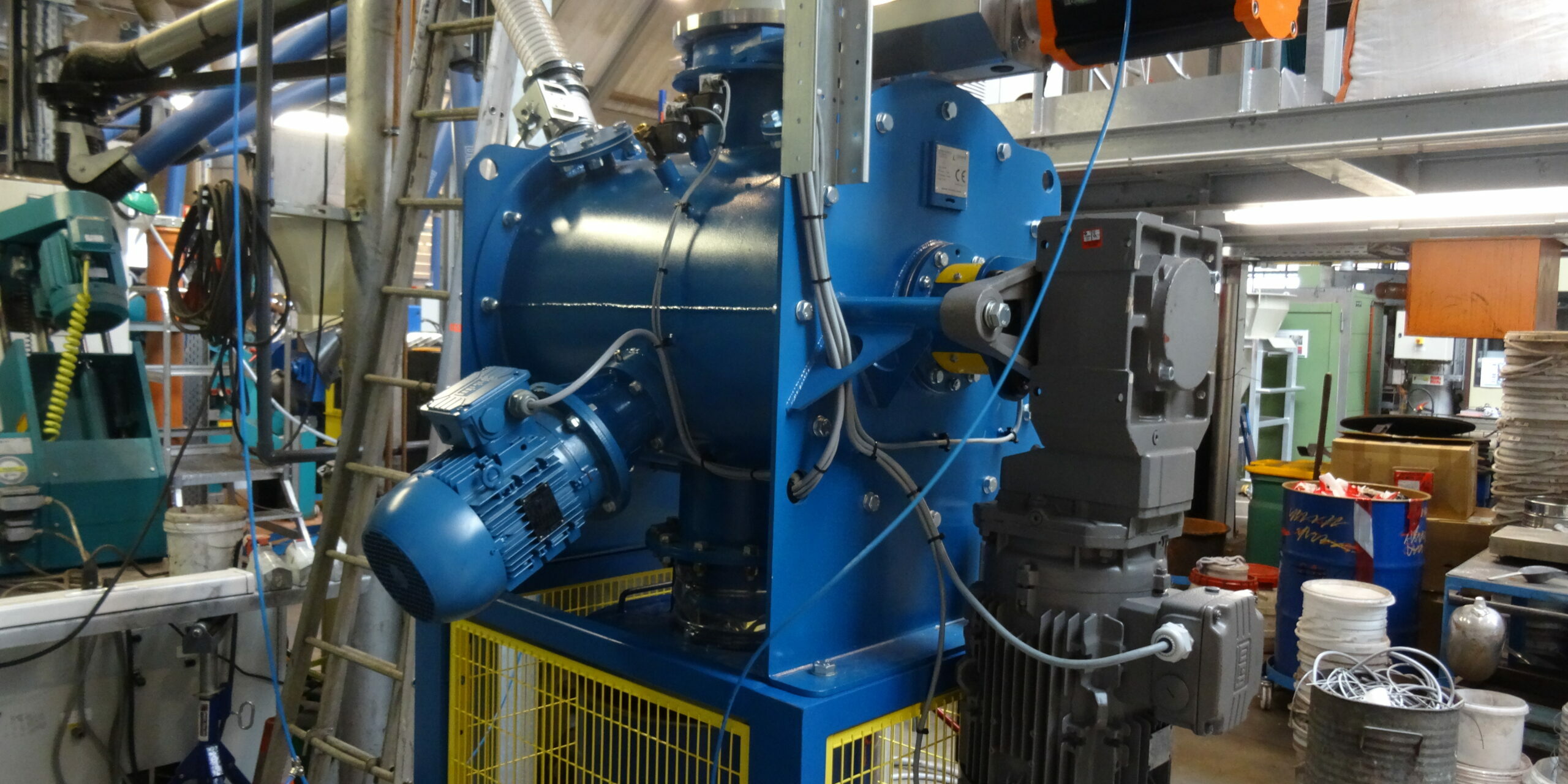

Lessine’s ploughshare mixers provide energetic and rapid mixing for demanding powders and blends, ensuring perfect homogenization in minimal time.

Operating principle

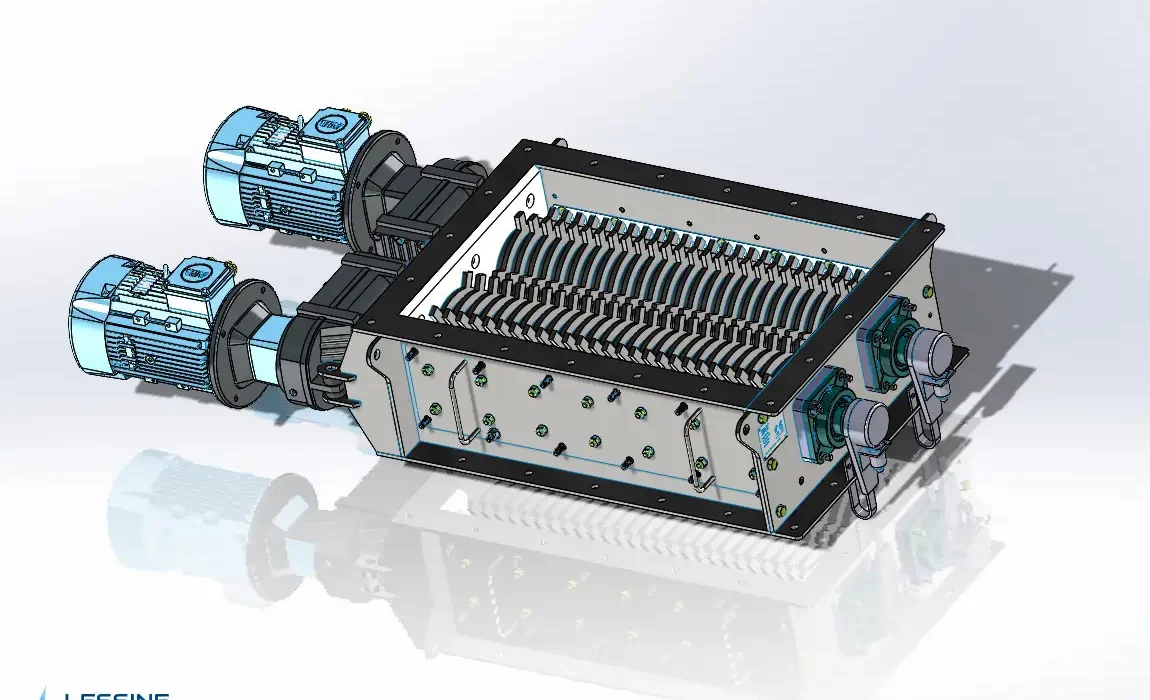

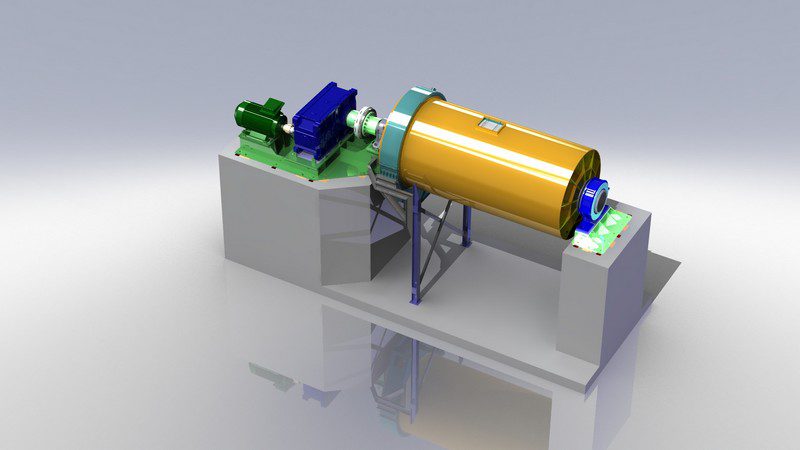

Ploughshare or paddle mixers also known as single-shaft ploughshare mixer or intensive powder mixer are equipped with ploughshare or paddle-shaped tools fixed on a rotating shaft, ideal for high-quality mixing. The ploughshares or paddles are profiled and oriented based on the nature of the products to ensure vigorous mixing by lifting and intensively blending the materials. Ploughshare mixers are used for mixing powders and granules, humidifying, agglomerating, coating, or even as reactors for certain chemical reactions.

This process guarantees fast and efficient homogenization. Liquid injection is also possible during the mixing process to add liquid ingredients for impregnation or coating as well as heating or cooling of the through during the blending process.

Applications of ploughshare or paddle mixer (single-shaft ploughshare mixer, intensive powder mixer)

The ploughshare mixer is ideal for the following industries :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

Advantages

- Very short mixing times

- Compact and efficient solution

- Discharge through one or more hatches or full opening

- Maximum homogenization of the mixture

- Available for continuous or batch processing

- Option for heating or cooling the material

- Easily replaceable and adjustable ploughshares/paddles

- Manufactured in different types of steel or stainless steel. Abrasion-resistant solutions available (wear plates, paddle/ploughshare reinforcement, etc.)