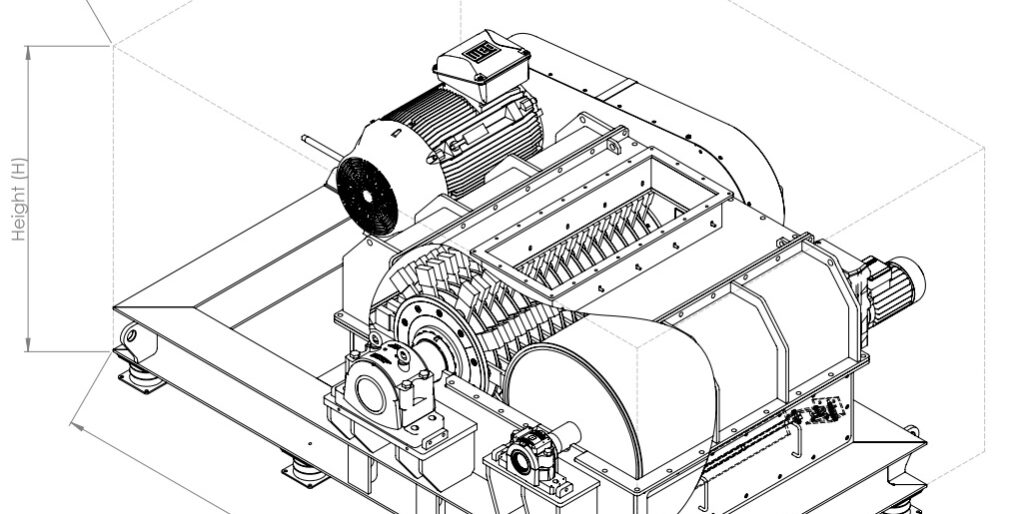

Crushing solution for difficult materials

Lessine’s fertilizer hammer roller mills are designed to efficiently grind wet, sticky, or difficult materials. Thanks to its technology combining crushing and impact, these mills ensure a high reduction ratio for various industrial applications.

Operating principle

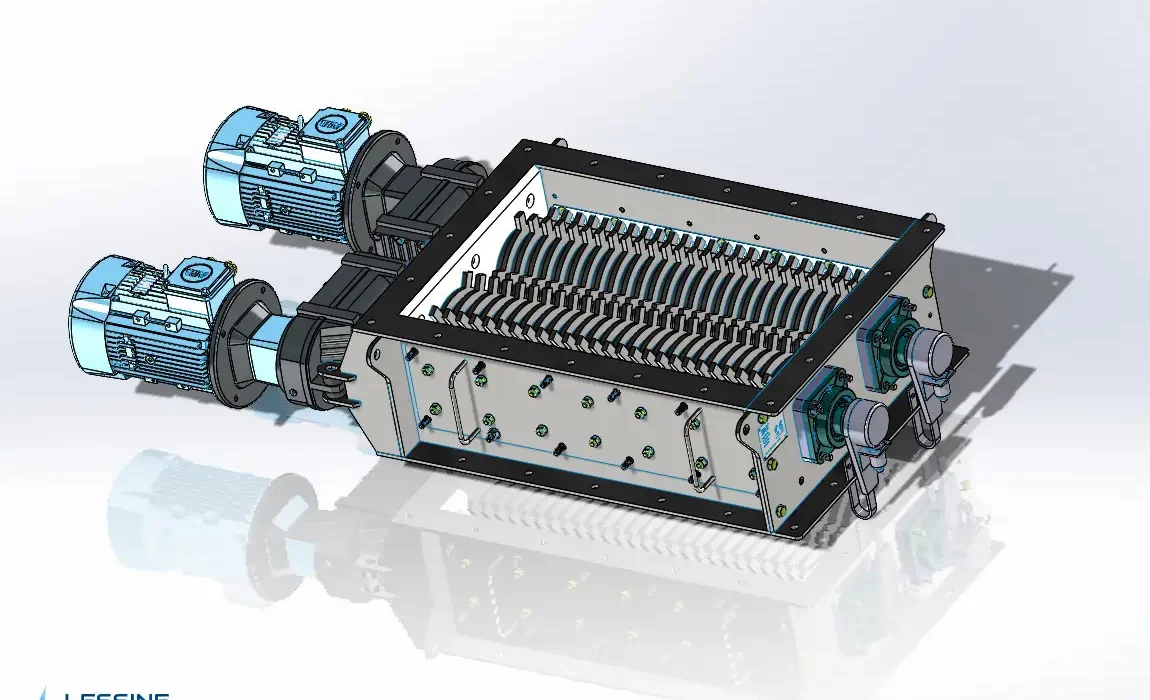

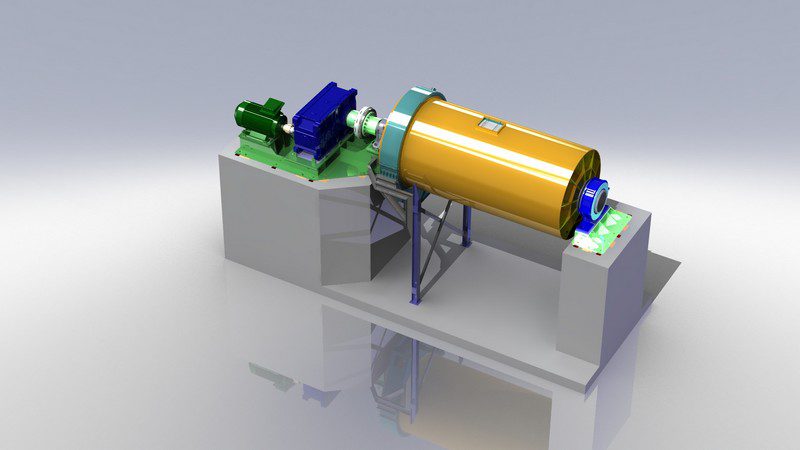

Fertilizer hammer roller mills, also known as hammer roller mill use pendulum hammers mounted on a rotor spinning at medium speed. These hammers impact and project the product against a rotating roller. This roller receives the materials thrown by the hammers and participates in their final grinding, allowing for precise particle size. This combination of crushing and impact ensures effective particle size reduction.

A scraper cleans the slowly rotating roller in case of sticky material, ensuring consistent grinding efficiency.

Applications of the fertilizer hammer roller mill (hammer roller mill)

The fertilizer hammer roller mill is suitable for intensive use with sticky, wet, or difficult products in the following sectors :

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

Advantages of the fertilizer hammer roller mill

- High reduction ratio

- Easy access for inspection and maintenance

- Scraper to keep the roller clean

- Minimal fines production during grinding