Solution for milling small quantities of bulk products

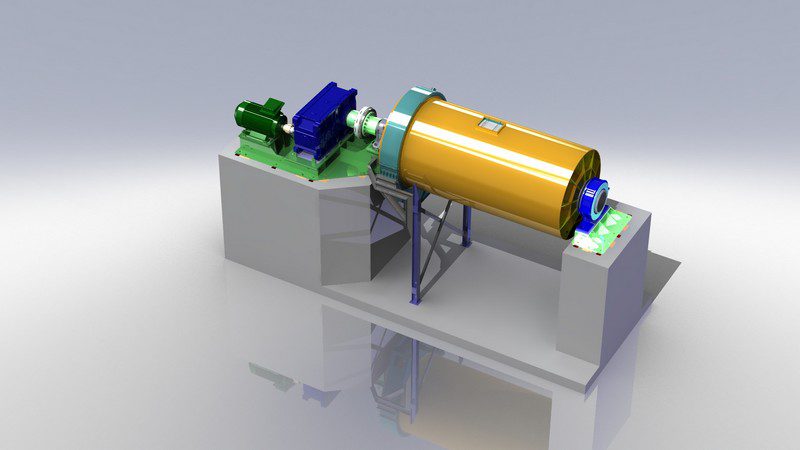

Lessine’s laboratory ball mills offer a highly suitable solution for milling small batches. They provide remarkable versatility to adapt to a wide range of applications across various industrial sectors.

Operating principle

Our laboratory ball mills also known as ball mill or ball grinding mill are designed for the milling and homogenization of a wide range of materials. Comprising a rotating (removable and interchangeable) drum, it uses grinding media to process the material to be milled. The material is milled by impact, friction, or attrition, thanks to a precisely optimized rotation speed.

Range of the laboratory ball mill

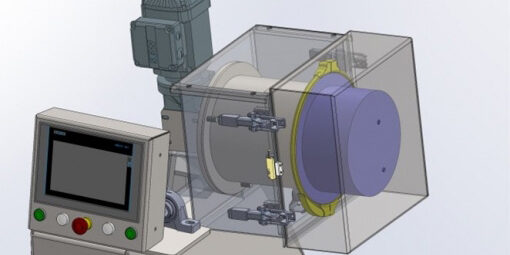

Tilting jar mill :

- Suitable for laboratory tests on a machine representative of industrial ball milling

- Tanks with a total capacity of 7 to 10 liters to prepare 1 to 3 liters of material per batch

- Easy loading and unloading of the product thanks to the tilting tank

- Robust and easy-to-use device,

- Adjustable rotating speed.

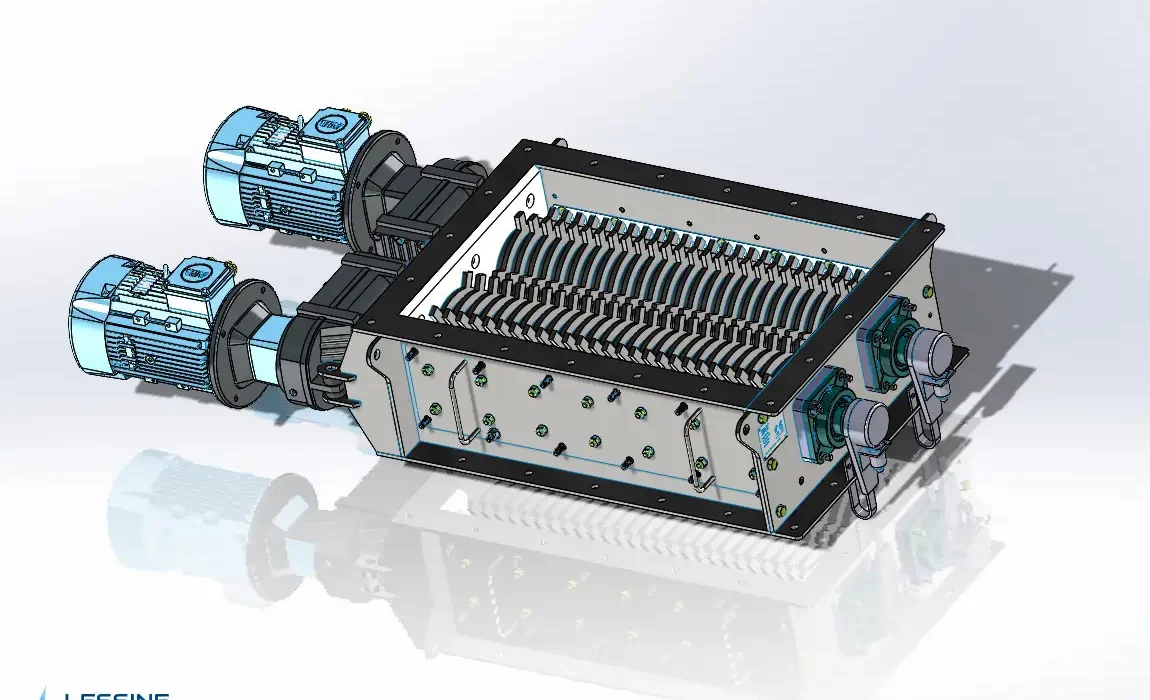

Multiple jar mill :

- Different models according to the geometry and volume of jars up to 15 liters capacity

- Adjustable for different jar geometry

- Multiple jar execution with up to 3 levels for the production of multiple batches simultaneously

- Adjustable rotating speed in accordance with jar diameter.

Applications of the laboratory ball mill (ball mill, ball grinding mill)

The laboratory ball mill is widely used in the following sectors :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages of the laboratory ball mill

- Processing of dry or wet materials

- Suitable for small quantities

- Minimum footprint

- Versatility

- High reliability

- Adjustable fine particle size and particle size distribution