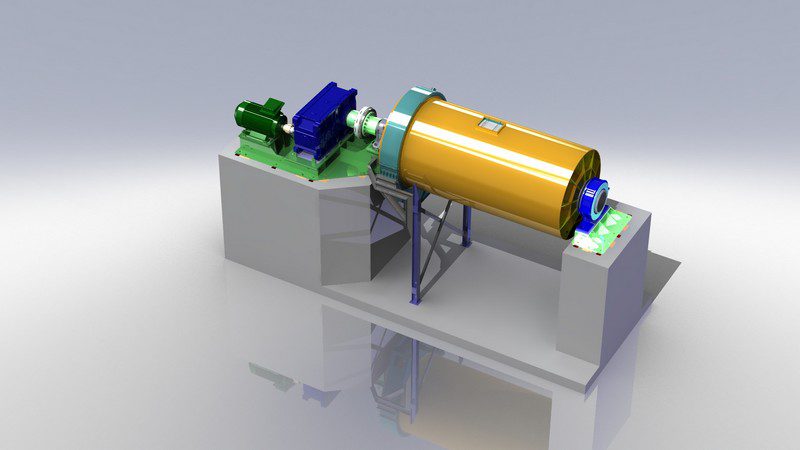

Optimized drying and grinding process

Lessine’s dryer-pulverisers combine grinding and drying in a single process, enabling simultaneous optimization of both procedures.

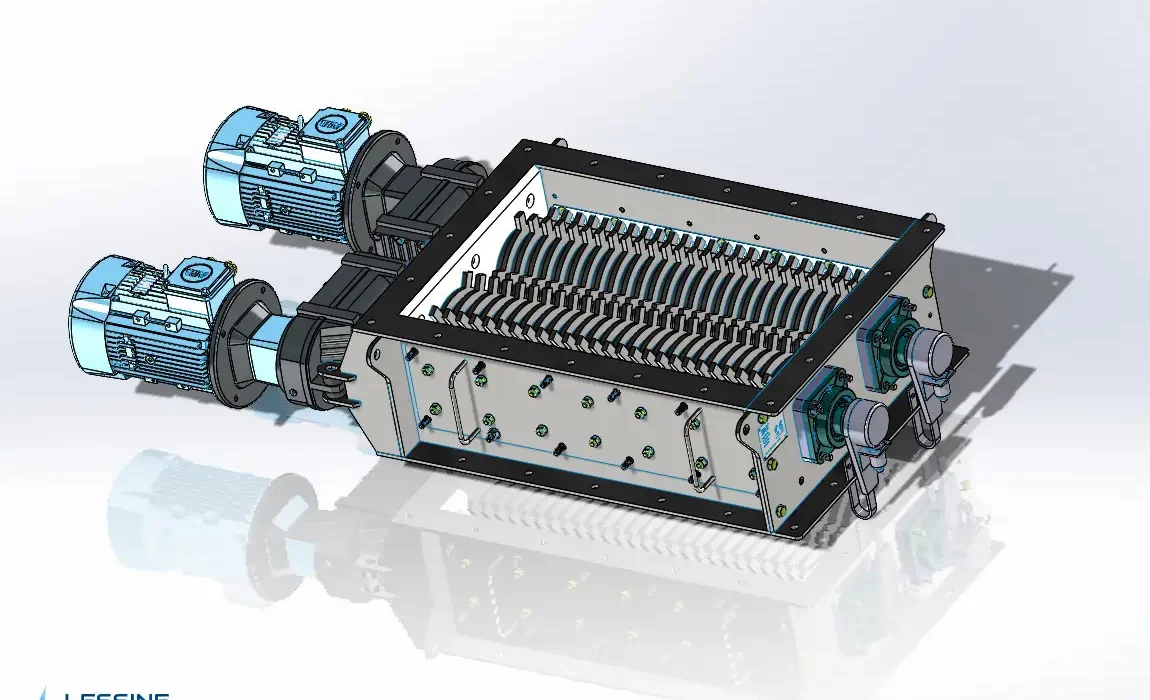

Oparating principle

Dryer-pulverisers also know as mill dryers are designed to perform grinding and drying simultaneously, with maximum efficiency. The product is fed into the unit and comes into direct contact with hot air in the grinding chamber. The increase in surface contact between particles and hot air, generated by grinding, optimizes and accelerates the drying process. In turn, drying enhances grinding by increasing the product’s dryness. The grinding process can be adjusted through multiple stages to achieve the desired particle size. The hot air passes through the feed chute, flows through the pulveriser, and is then filtered and expelled by an exhaust fan.

Applications of dryer-pulveriser (mill dryer)

The dryer-pulveriser is ideal for wet and/or sticky products in the following sectors:

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages

- Grinding and drying in a single process

- Savings in thermal and electrical energy

- Adjustable particle size and final moisture level

- High evaporation capacity