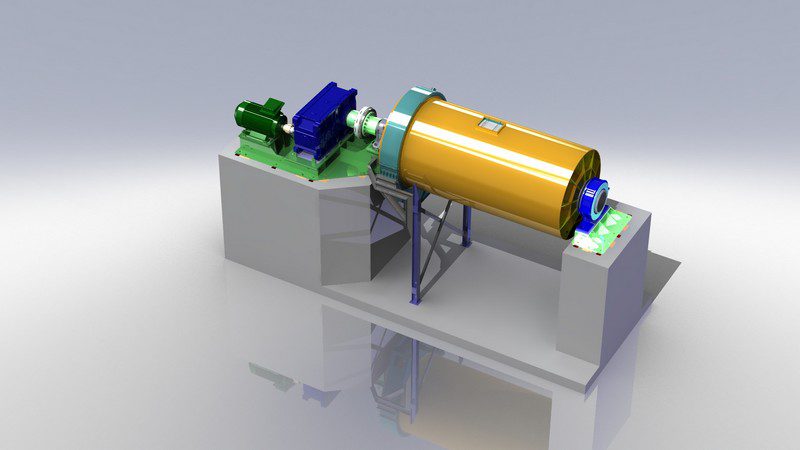

Blending solution for drums of all sizes

Lessine’s Drum Mix Master enable efficient homogenization or re-homogenization of mixtures in batches within drums of all sizes and designs. Designed to offer flexibility and efficiency, they adapt to various industries and product types.

Operating principle

Drum Mix Master also known as drum mixer, barrel mixer, drum blender or drum turner recipes are prepared in suitable containers. The drum to be blended is attached to a rotating shaft, easily securing to the blender’s support and following its rotational movement. An off-center position with rotation around a non-vertical axis optimizes blending quality and time. Manual and/or automatic adjustment fastening systems adapt to a wide range of drum types and sizes on the same blender, offering increased flexibility.

Our blenders are available in standard sizes in painted steel or stainless steel.

Our range includes two to three types of drum blenders :

DMM200 : This is the classic model for drums ranging from 50 to 220 liters. The drum is manually secured to the rotation axis with various fastening options.

DMM200 AT : Automated tilting system for easy handling and securing of drums. Various manual drum fastening systems available.

DMM LABO : This laboratory version allows mixing small containers or interchangeable vessels (V-blender, biconical, parallelepiped, etc.) of various volumes ranging from 0.2 to 9 liters.

Applications of Drum Mix Master (drum mixer, barrel mixer, drum blender, drum turner)

The drum mix master is used in various industrial fields such as

- Circular economy and valorization

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages

- Blend products directly in storage drums

- Adaptability to different drum capacities

- Easy transition from one container to another

- Ability to place several types of drums in one support

- Maximum flexibility

- No cross-contamination between different blend