Reliability, safety and efficiency for bulk products

Lessine’s Big Bag filling and emptying stations are designed to optimize the handling of powders, granules, and other bulk materials in Big Bags, while ensuring reliability, safety, and efficiency.

Operating principle

- Big Bag filling station :

- The Big Bag is placed on a support frame or suspended using lifting forks.

- A hopper or feeding system controls the introduction of the product into the bag.

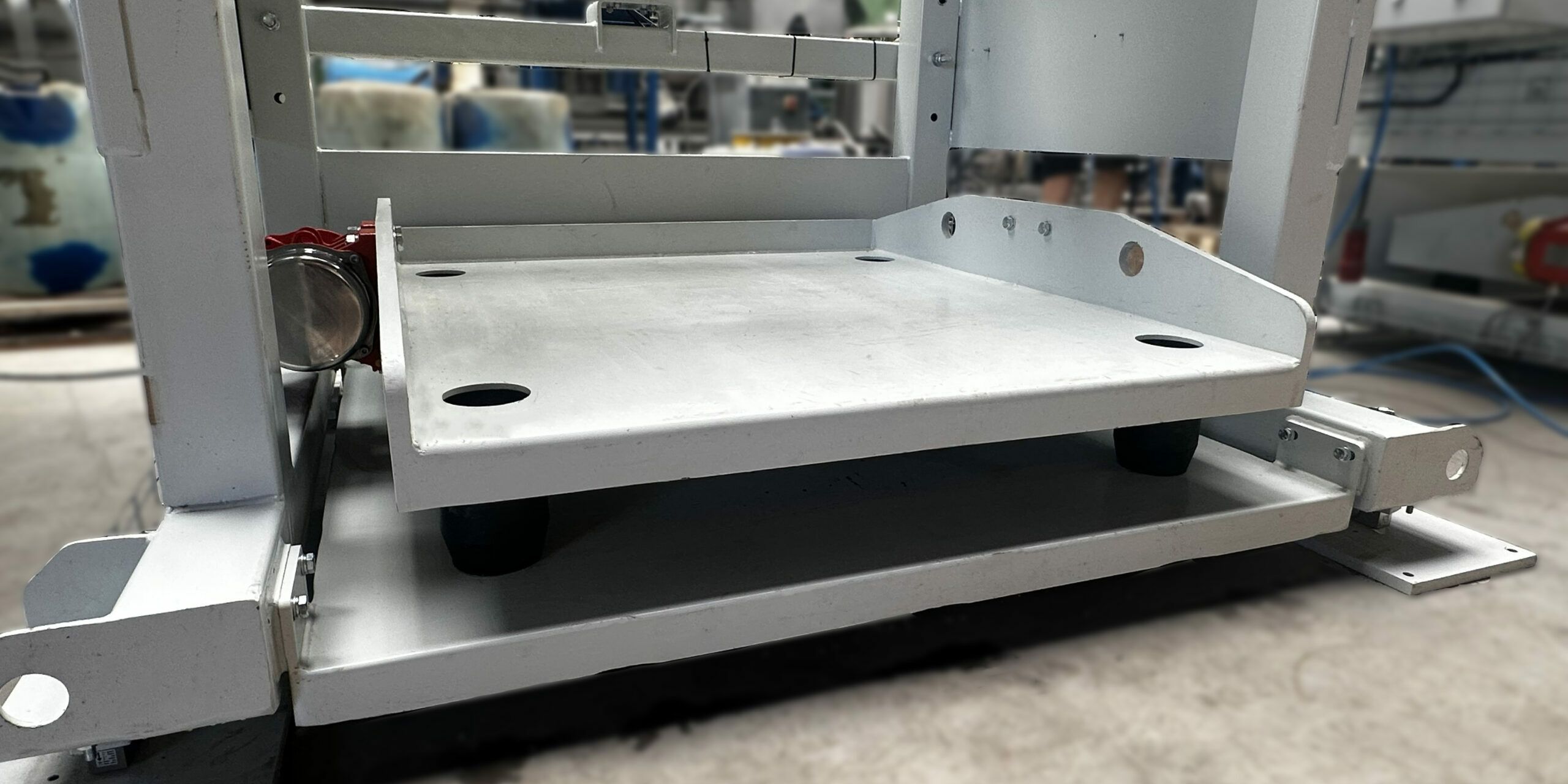

- The movable table ensures proper bag extension, allowing for optimal filling.

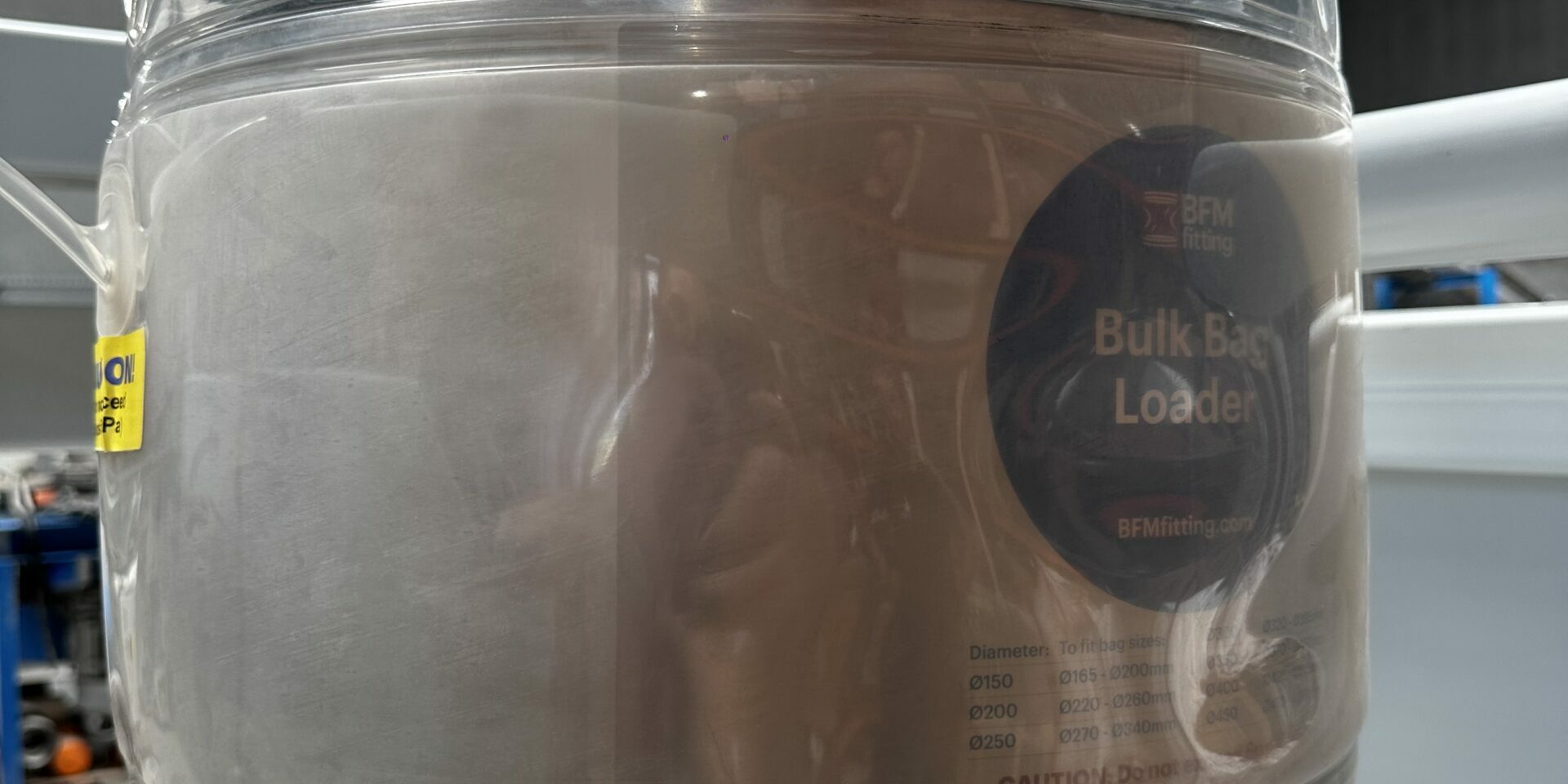

- Sealing devices guarantee the absence of leaks during the filling process.

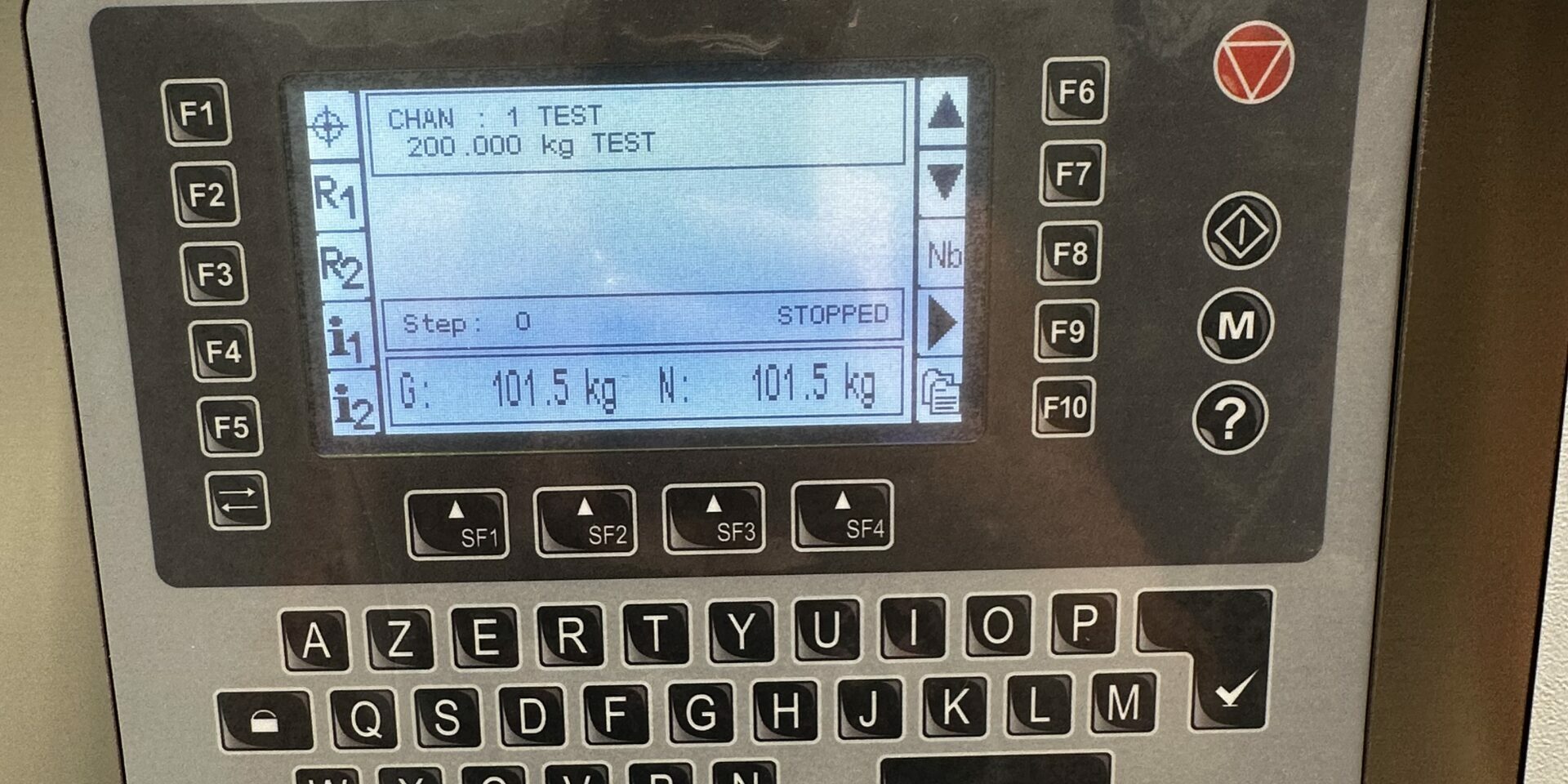

- A weighing system can be integrated to ensure accurate loading.

- A vibration system helps distribute and compact the product evenly.

- Standard Big Bag emptying station :

- The Big Bag is placed on a emptying station equipped with a support frame.

- Secure opening solutions (manual or automated) release the contents of the bag either through the discharge spout or by creating an opening at the bottom of the Big Bag.

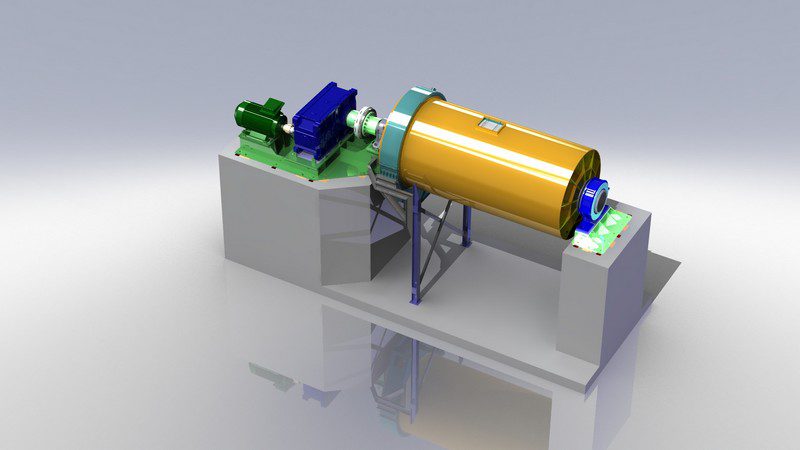

- A receiving hopper guides the material towards a conveyor, screw, or another extraction system.

- A Big Bag massaging system helps optimize the discharge process.

- Dust extraction connections are provided to ensure dust-free emptying of Big Bags and a clean working environment.

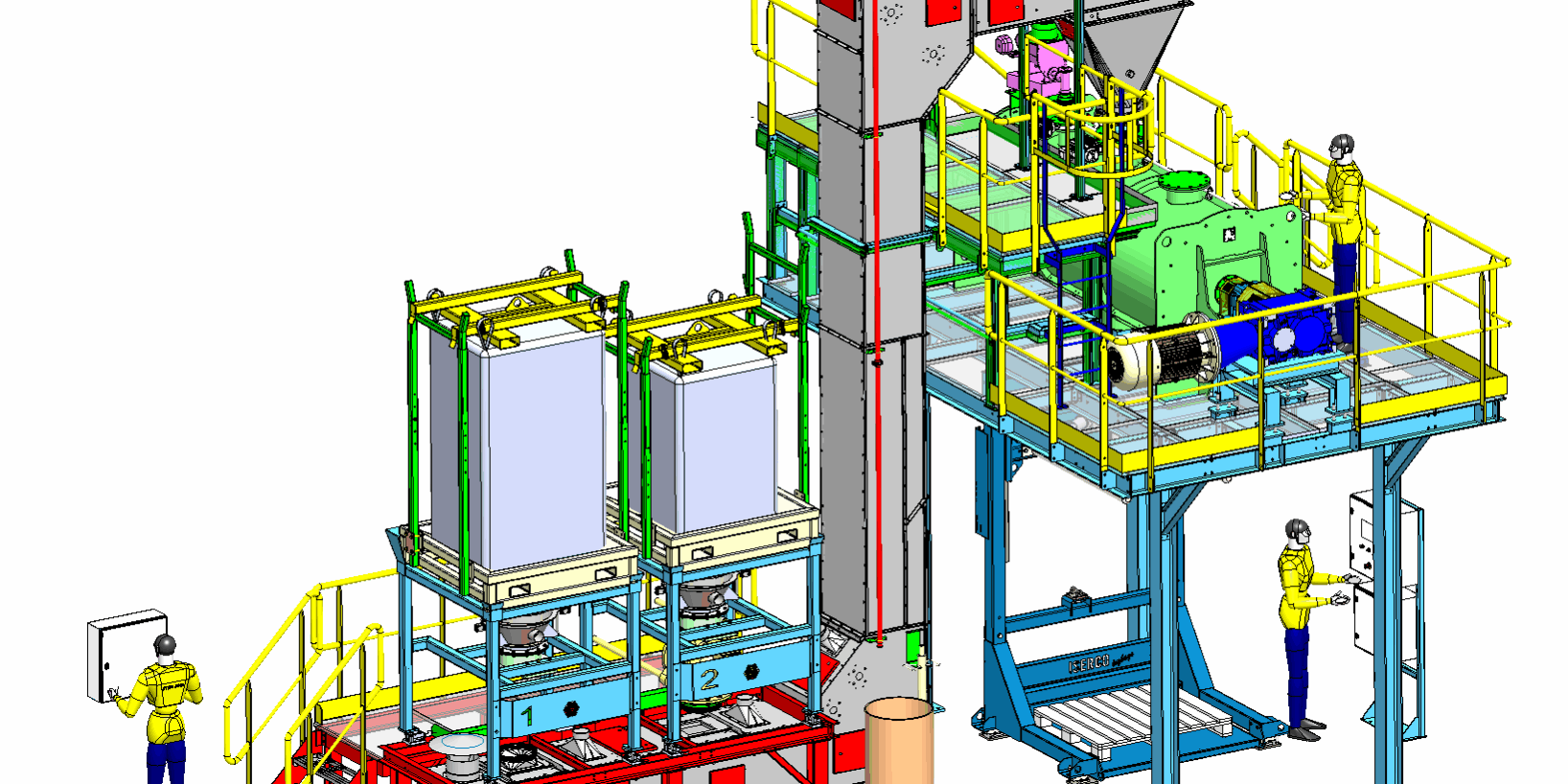

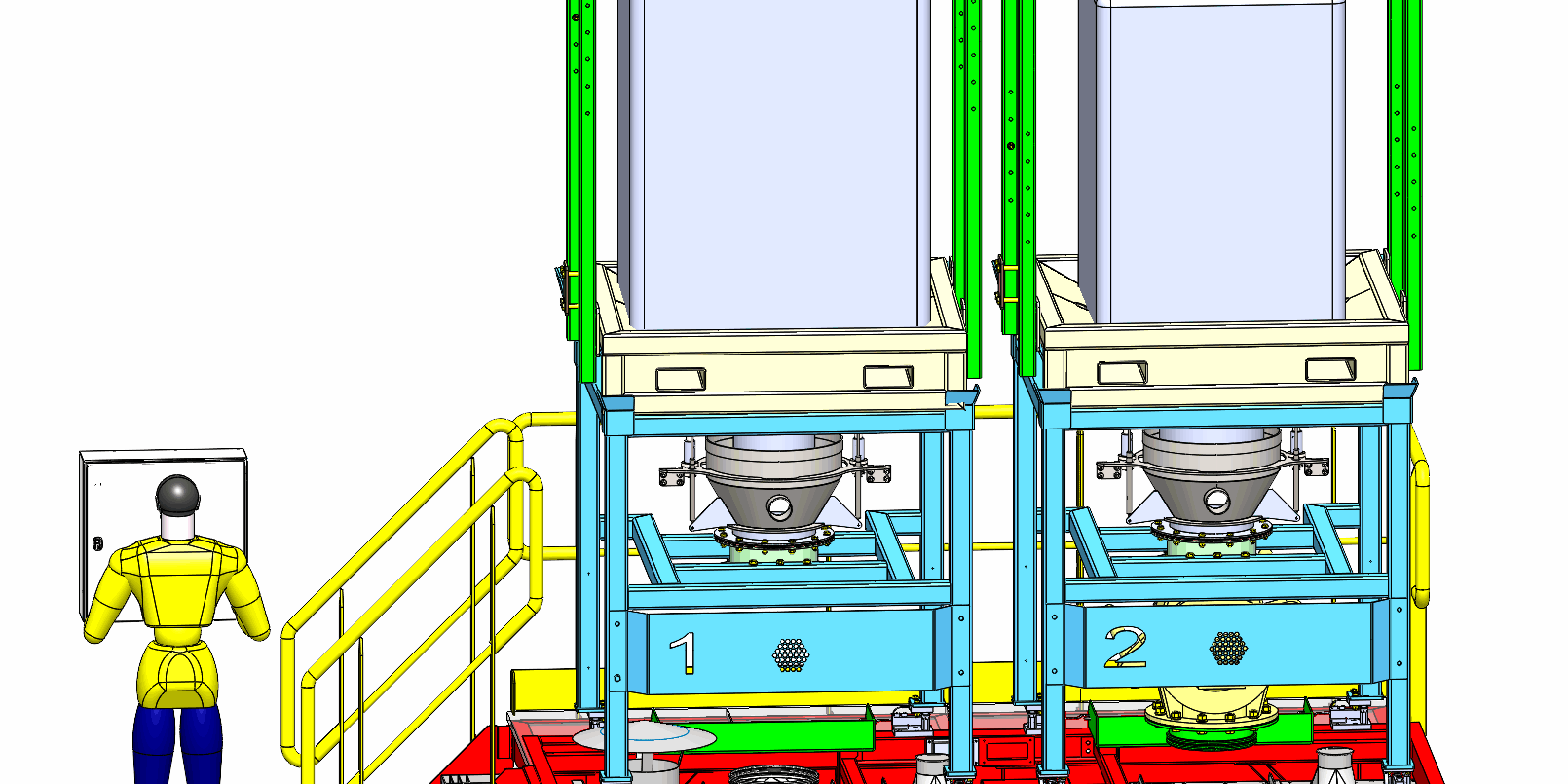

- Big Bag emptying systems in confined spaces :

- The Big Bag is positioned on a robust support frame and handled using a forklift, ensuring precise and quick placement.

- Two discharge bases allow for the simultaneous emptying of two Big Bags, ensuring a continuous feed to the process without production interruption.

- The securing system is equipped with a hermetic connection device, guaranteeing a perfect seal between the discharge spout and the receiving hopper.

- Discharging is carried out without any dust emission, even when handling fine or volatile products.

- The flow rate is precisely controlled by a rotary valve or airlock, ensuring a consistent and well-regulated product feed into the process.

- Material transfer is carried out via a sealed conveyor equipped with several dust extraction ports to efficiently capture residual particles and maintain a clean working environment.

Applications of Big Bag filling and Emptying stations

Rotary valves are particularly suited for distributing bulk products in the following industries :

- Circular economy and recovery

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages

- Equipment designed to minimize risks associated with Big Bag emptying.

- Reduced risk of dust contamination thanks to fully sealed solutions.

- Complete system operating in a confined environment.

- Large-opening Big Bag cutting system for fast container emptying.

- Capacity of up to 20 Big Bags per hour.

- Empty Big Bag compaction system into a bag or another Big Bag.

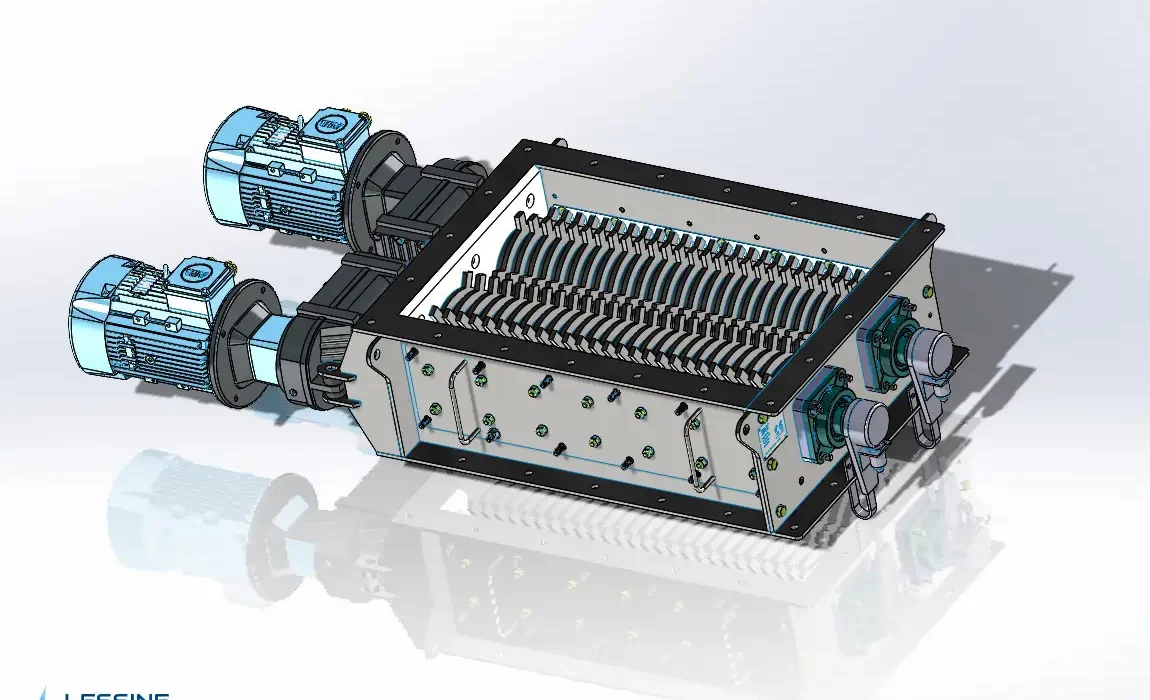

- Integrated twin-shaft crusher for material deagglomeration.

- Automatic control via PLC and touchscreen with SCADA visualization.

- Adaptable to various Big Bag sizes and material types.

- Weighing systems ensure precise and controlled filling or discharging.

- Modular design allowing the integration of accessories (vibrators, filters, etc.) according to specific needs.