Gentle drying of materials

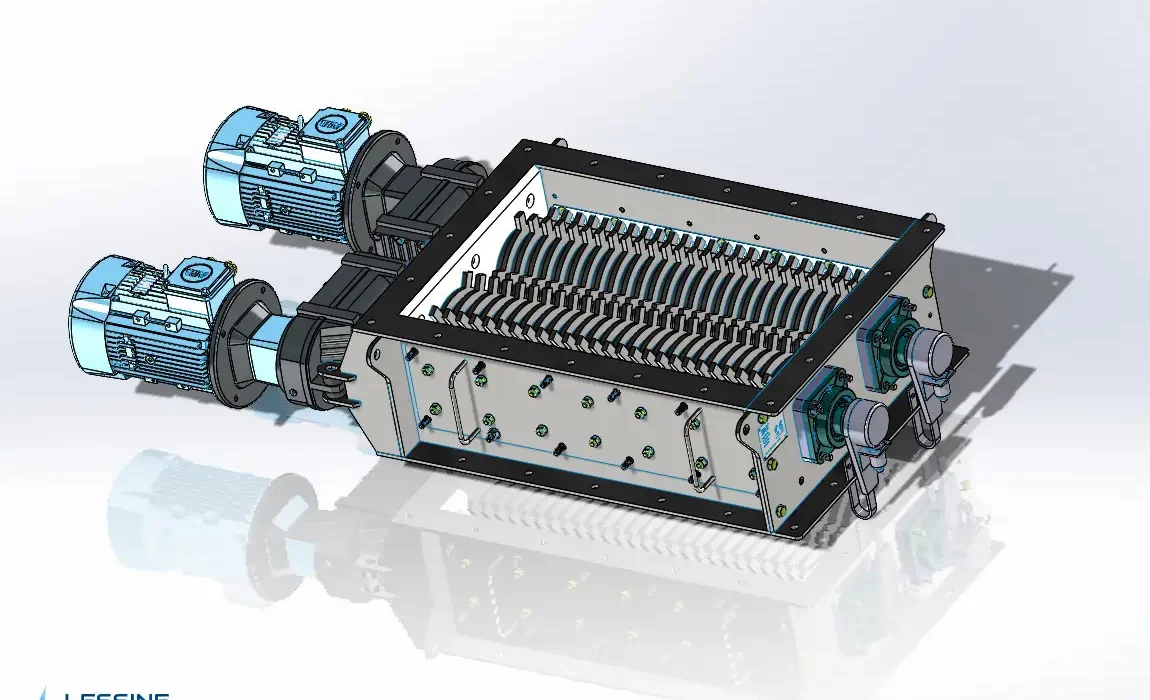

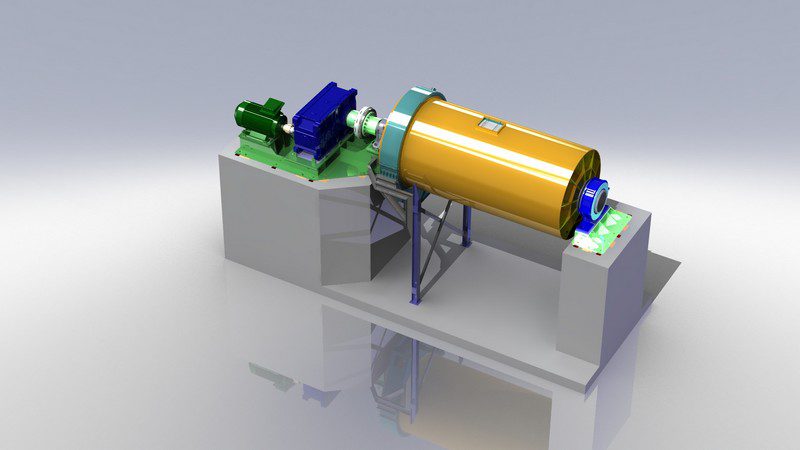

Lessine’s rotary drum dryers stand out for their versatility in handling various materials and their robustness. Their direct or indirect drying systems allow for deep material drying.

Operating principle

In a rotary drum, drying can be done in either direct or indirect mode :

Direct mode: the product is dried by injecting a stream of hot air, either co-current or counter-current. During this process, the material follows the drum’s rotation, and the internal lifters agitate the product, gradually moving it toward the outlet.

Indirect mode: the heat exchange surface is generated by the drum shell or by tube exchangers installed within the drum, ensuring the evaporation of water from the product.

Applications of rotary drum dryer (rotary dryer)

The rotary drum dryer is versatile and suitable for the following sectors :

- Circular economy and recovery

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages

- Drying without mechanical alteration of the material

- Co-current or counter-current direct drying

- Suitable for various materials

- Drying in direct or indirect mode

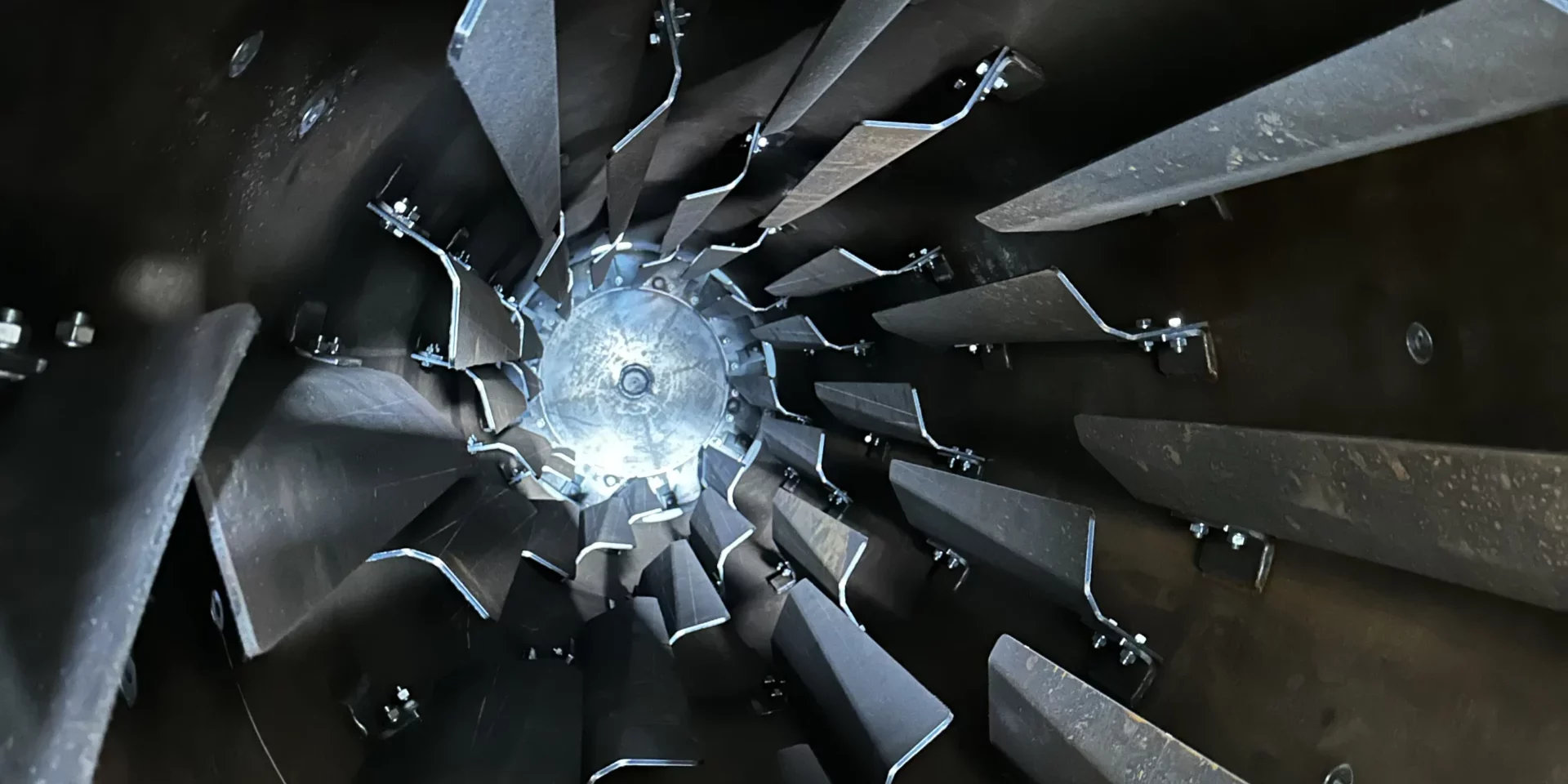

- Adjustable lifter design

- Various possible energy sources (gas, fuel, electric, biomass, waste heat, etc.)

- Drying and cooling possible in one equipment