Precise crushing solution for bulk products

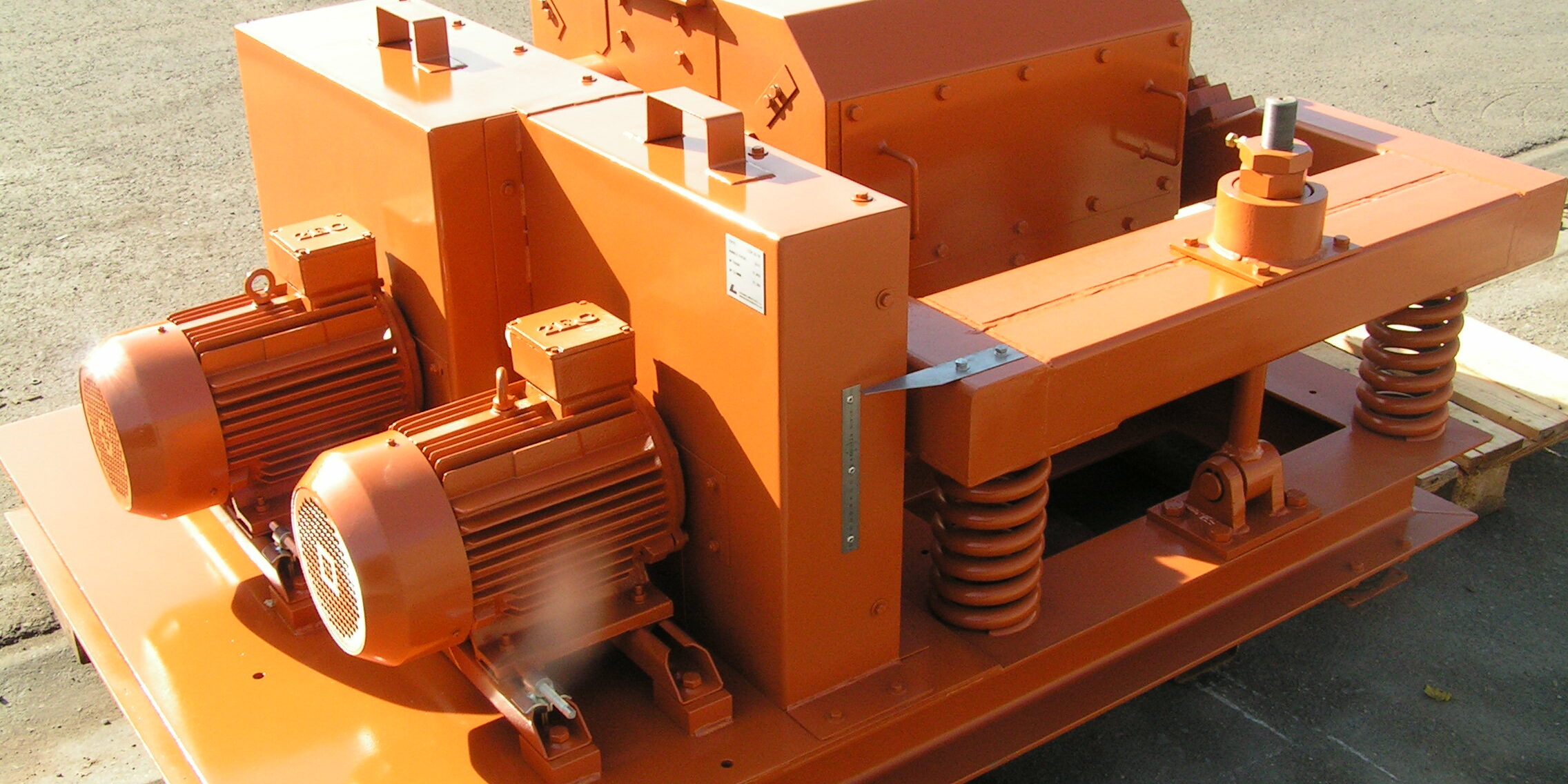

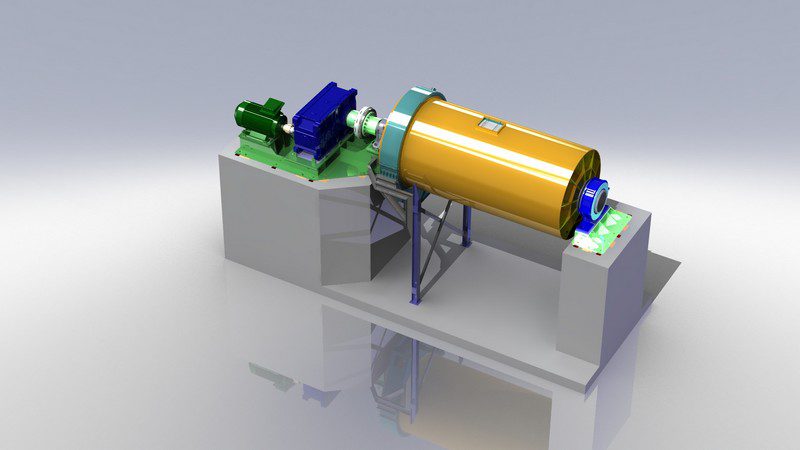

For primary, coarse, or medium crushing, double roll crushers allow for the crushing and/or tearing of material while maintaining a tight particle size distribution. This machine is ideal for various industrial applications requiring adjustable and reliable crushing.

Operating principle

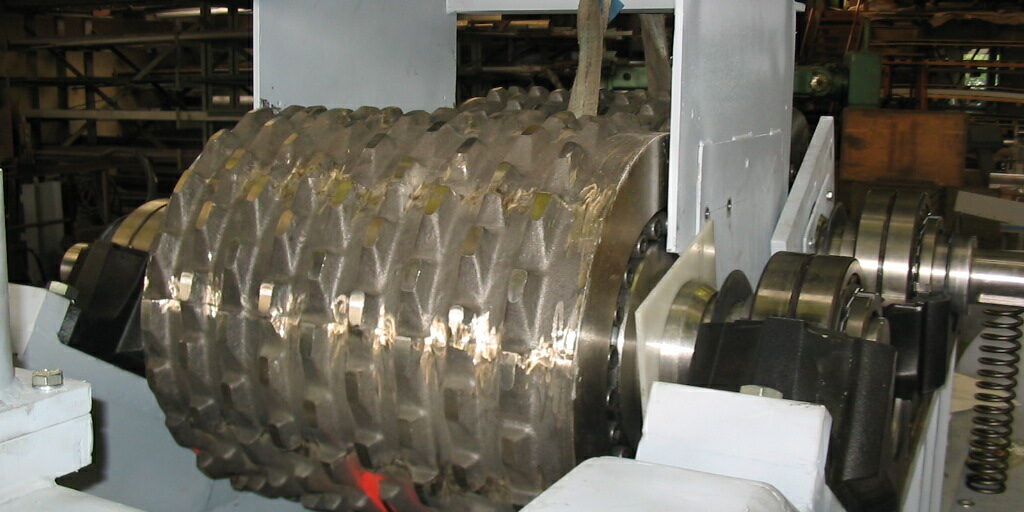

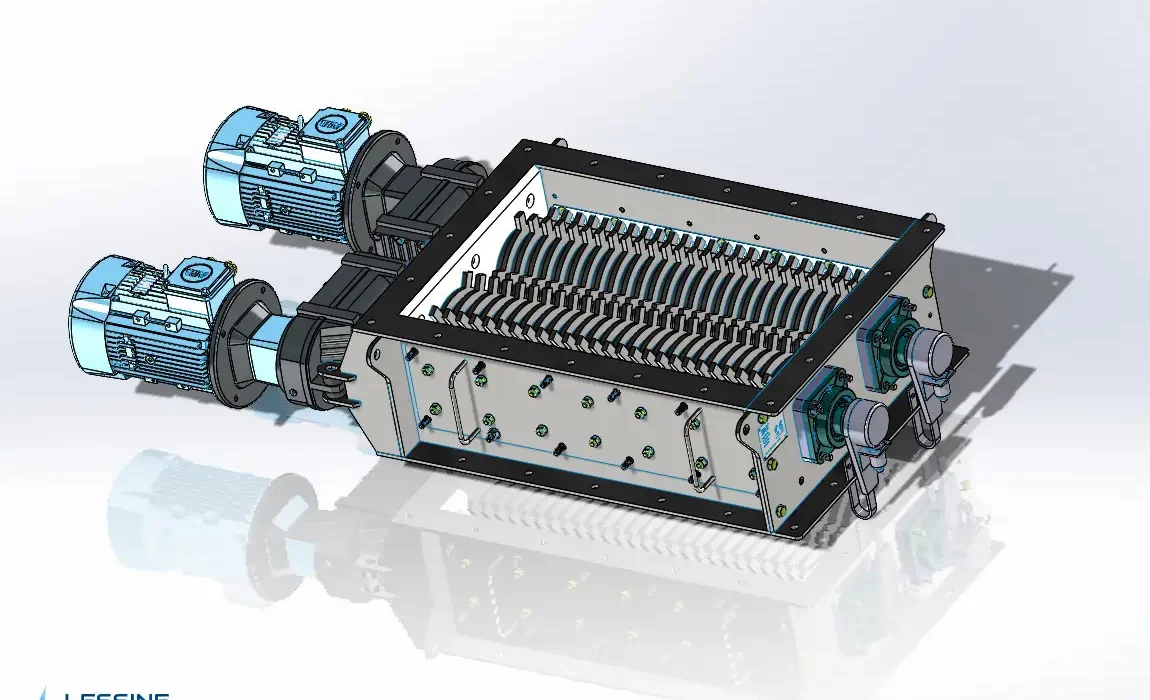

Double roll crushers are also known as double roll mill, roller mill, or roller press. Material is crushed between two rollers, rotating slowly or quickly, smooth or equipped with teeth or grooves, selected according to the nature of the product and the desired crushing. The gap between the rollers is adjusted according to the desired particle size, and the crushing generates very few fines.

The compression force between the two rollers is provided by calibrated springs or hydraulic pistons.

Applications of the double roll crusher (double roll mill, roller mill, roller press)

The double roll crusher allows for coarse reduction of hard, abrasive, and possibly sticky materials in sectors such as :

- Circular economy and recycling

- Minerals and ores

- Fertilizers, chemicals, fine chemicals

- Food and pharmaceuticals

- Metals and precious metals

Advantages of the double roll crusher

- Reduction ratio: 5 to 10:1

- Types of rollers: toothed, grooved, or smooth

- Tight particle size distribution

- No product heating

- Minimal dust during crushing

- Compression springs/hydraulic pressure adapted to the crushed product

- Passage of foreign and/or uncrushable objects without damaging the machine