Efficient solution for IBC container mixing

Lessine’s industrial container mixers offer the perfect solution for fast and homogeneous mixing directly within the container. They are suitable for all industries and a wide range of powders. Lessine also provides filling, emptying, and cleaning stations for IBC containers.

Operating principle

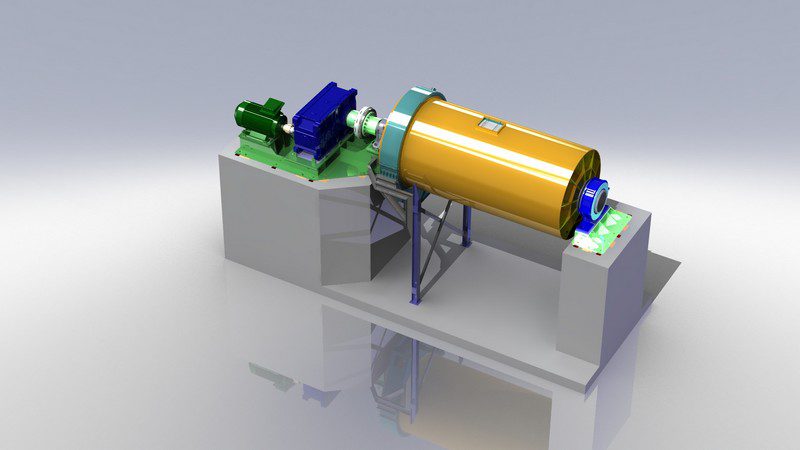

The industrial container mixer is also known as IBC blender.

The container is placed on the mixer’s platform and secured in position by an automatic locking system. The mixing occurs through continuous rotation of the container on a central asymmetrical axis, generating optimal mixing.

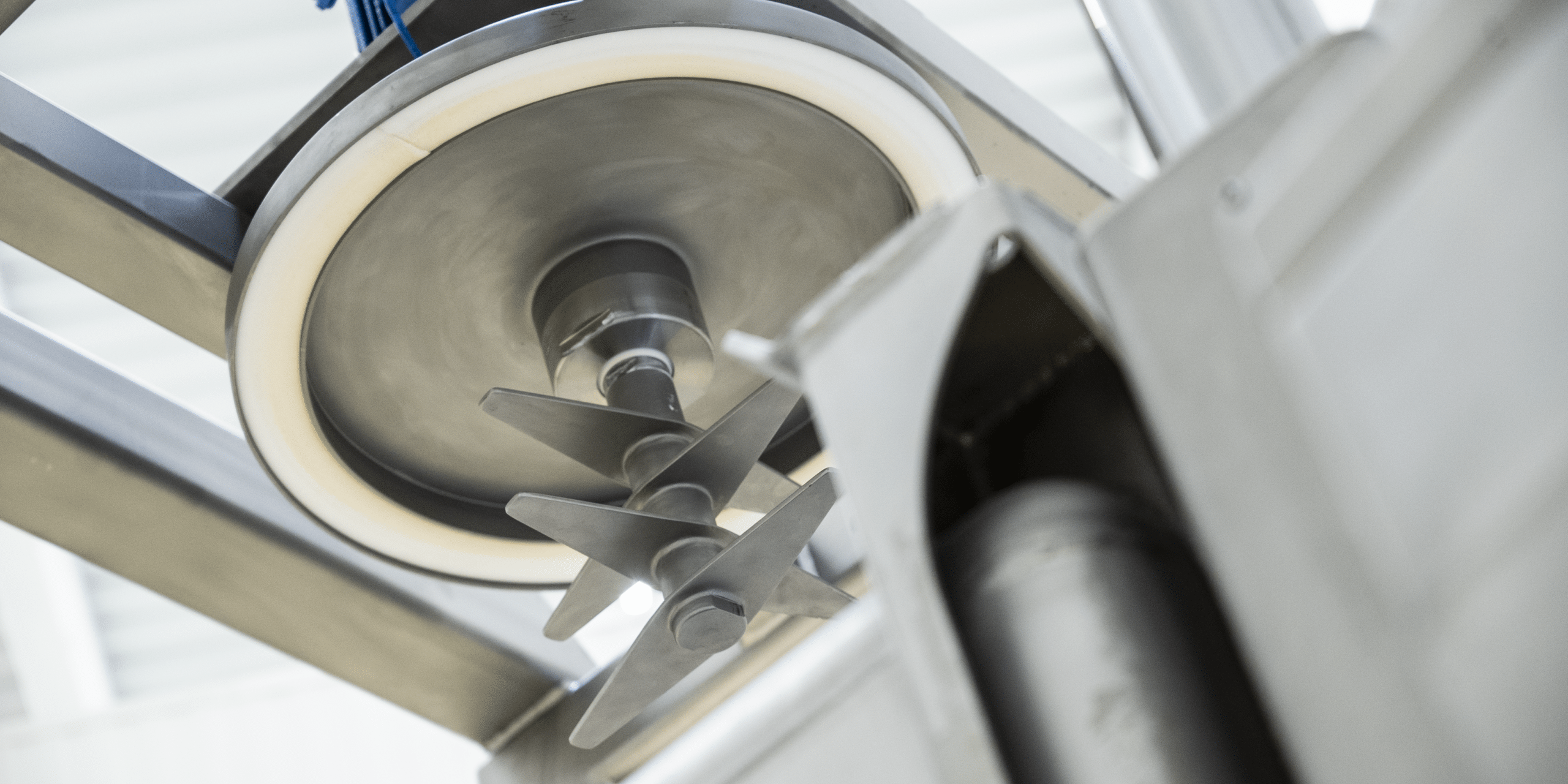

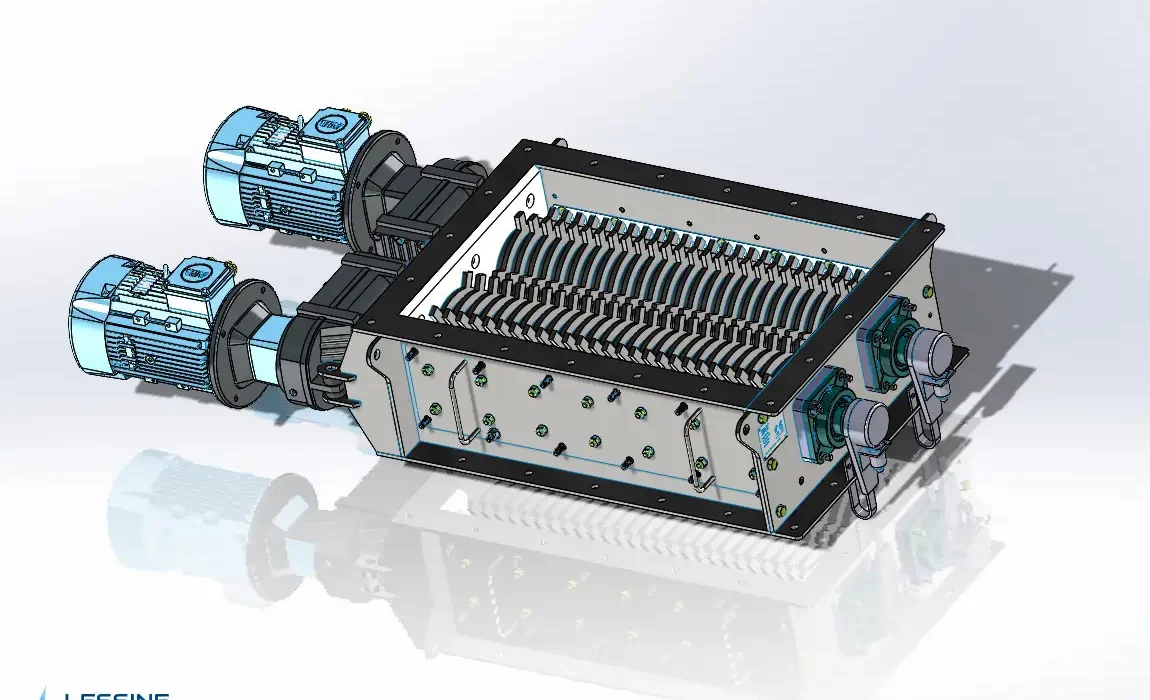

An energetic mixing system (Energizer) can be added to enhance the mixing of products with agglomerates or complex recipes.

Applications of industrial container blender (IBC blender)

The industrial container mixer is ideal for all batch mixing applications where production benefits from confinement or frequent recipe/lot changes without cross-contamination.

It is especially used in the pharmaceutical and food industries, where high hygiene levels are required, as well as in the metal powder industry for particle size reconstitution or additive incorporation.

Advantages

- Various container shapes and sizes adaptable to a single model (from 200 to 3000L)

- Mixing performed directly in storage containers

- Variable mixing speeds

- Secure locking system

- Homogeneous powder mixing